Supporting Our Customers Is A Key Priority.

IMTS 2018 is Only Hours From Closing

IMTS is almost Finished …..

As is customary on the last day of the show I spend the time organizing the last details of the show move out, Bill Of ladings, and also getting the leads into our guys hands so they can start reaching out to all the people that visited us this week. Reflecting opn this show, it was amazing. We had success beyond our expectations not only selling machines but also displaying our newest technology. It is satisfying to not only sell equipment off the floor, but for people to let us know that they stop by every two years to “ see what is the latest and greatest that we brought “

This is a complement to all those at Royal Master who put in the extra hours and worked to make this a success. The bottom line is that it was a good show and I hope we repeat it again in two years!

As is customary for IMTS Rookies we had two new ones this year and they did not disappoint. They wore the Helmet proudly, and Alex the Intern added the appropriate bicycle flag to the ensemble. IT was a good touch. Both John and Andrew made new friends as they introduced themselves “ Hello my name is Andrew and I am an IMTS rookie. “

Oscar also made the trip out for set-up and he also was a champ wearing the helmet proudly during the set-up days. All three know that they will be posted on the blog.

I was also interviewed for IMTS TV which was a fun experience, ...

Day One of Set-up and The Truck That Was Just Long Enough

we loaded up the truck and it was just long enough. We had to squeeze everything together to make sure it all fit, however we had three inches to spare.

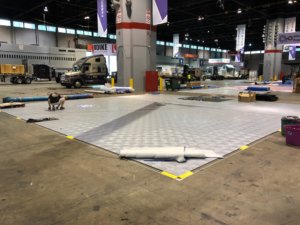

Day one is done setting up the show, nothing crazy other then laying the floor and chalking out the machines to ensure we like the layout.

Tonight’s dinner will be the Purple Pig. Great food and better atmosphere.

https://thepurplepigchicago.com/menu/

Tomorrow we welcome in Alex and Oscar into the set-up mix. Oscar is a first time IMTS guy so he will be donning the pink bicycle helmet before he leaves.

Meet Alex the Intern!

As in past years we hire an intern for the summer. We ask our intern’s to summarize their experiences at the end of the summer and this is her’s. Also as a rite of passage it is a requirement that she drives the forklift……….

ALEX’S BLOG POST

Wow, where to begin.

I would have never thought when I started here at RMG that I would learn as much as I did this summer. I can honestly say that it is one of the best environments I have ever worked in. I will leave here not only having learned so much about IMTS, but also having learned a lot about how important it is to work fluidly as a team and to have fun no matter what you’re doing. This is a family that I feel very lucky to have been a part of this summer, and I think any other intern that has the opportunity to work here would say the same thing.

Day 1: I walked in completely blind not knowing what this place even did or what would be expected of me. I had never worked in a machine shop before. I was paired with Michele to do inventory and immediately loved her energy. She was smart and funny and had this great vibe, and I knew right away I was going to like it here. Counting hundreds of little metal parts could quickly become tedious, but she didn’t make it feel that way. In fact, everybody here knows how to make the best of what they’re doing, usually by making sarcastic jokes. (Or if you’re Alan or Stacy, by singing.)

That morning, I saw a very tall man running around all over the place giving direction and joking around with everyone. It was John, the boss; the man in charge. Not knowing him yet, I was intimidated a bit at first and now I know I couldn’t have been more wrong. John is one of the most generous, kind, caring bosses I have ever had, and I have had my fair share of jobs. He is extremely easy to talk to and made the process of learning something completely new easy, even though his favorite thing to do when I have a question is to run away and pretend he doesn’t see ...

Three days until we ship a lot of machines to IMTS 2018

There is 4 days to go until we do the packing of the truck. For those who are new to following my blog, it is a day that is filled with a lot of satisfaction. All of us at Royal Master have worked for 9 months to get to this day. We welcome the truck into the lot and when it leaves, we exhale. Rich and I split the show up into three sections, the 9 months of prep, “the show” and then the “after show”. The actual show is enjoyable for me, and it is the least amount of stress. I love talking to the people that come into the booth discussing the different projects that we are presenting, and past projects that are applicable to their particular application.

We are fortunate that our team at Royal Master is fully invested into he success of our company at the show. There are a lot of late hours, and people asked to do jobs that they normally don’t do, but the results speak for themselves. We are happy to share the results with our employees as they were a large part of the success of the show for us.

We are introducing our GX3 machine at the show. Its dual grinding wheel set-up allows for applications such as endodontic files be ground in 1/3 the cycle time of conventional systems. Its primary grinding wheel creates the initial part of the file, and then the secondary wheel creates the flutes in the part. Its pretty cool! The machine cones with a completely new look enclosure which makes the system look sleek and modern.

Our New Hi-Acc machine has a new operator interface. The 24” touchscreen interacts in a new way with the operator where as multiple screens can be open at one time making navigation easier. There is total customization for each operators preferences. Just like a memory seat in a car but for machine tools.

Of course will have a robotically loaded machine, Fanuc and Keyence are strategic partners on this project . We will also have a TG-12×8 thrufeed machine grinding 8000 parts per hour feedrate. You must stop by to see how we are doing this! In addition to all of this we have a lot of variety in equipment. Simple Thrufeed machines to highly automated systems. Our machines are not one size fits all propositions.

what happens when you bring your kids ...

IMTS 2018 and the Smartforce Student Summit

Watching your kids grow up is really an amazing thing. Many of you have seen my daughters grow up through blog postings and other conversations that I have had personally with many of you during shows as well as sales calls and other meetings. I am proud of both of them as they are both making their way in life. My oldest is a Sophomore in Highschool at Bergen Country Technical High School in Teterboro NJ. Ranked the #3 school in the state and #28 in the nation, she is taking full advantage of her opportunity. Her High school major is automotive engineering which mixes lab work ( good old fashioned shop class ) and classroom where she is learning CAD and CAM, making projects and implementing them into reality. Also look her and I in an Episode of Sticker Shock on Discover channel in early July. She will have her 1915 Model T on the show.

My youngest changes her mind daily in what she wants to be, and at 12 years old, good for her. She recently started discussing pharmacy or being a Dr. She is one to love school and is undeterred by volumes of work thrown at her. My wife and I feel a sense of pride everyday with these two.

Where this conversation is going is STEM and the IMTS student summit. At IMTS in September there is a student summit where school aged children are brought to McCormick place and are given an opportunity to see what opportunities are available in the world of manufacturing. Taken from the IMTS website:

Inspire Students to Pursue a Career in Advanced Technology

We hope you’ll consider bringing your students, their parents, and school administrators to the Smartforce Student Summit at IMTS 2018. Their experience will certainly help them connect school with real-world challenges and may inspire them to pursue a career in advanced technology. #LetsDoThis

In this industry we all realize that our future of manufacturing lies with this generation and their participation in the technology. The student summit should be more then a day out of school for these kids, its an opportunity to look into their future and hopefully later in life they see an opportunity to participate in the world of manufacturing. After all, that smartphone they use everyday would be here without people like us.

With IMTS coming up, we are bringing 8 ...

Just some thoughts…….

Time has certainly flew by as 2017 is coming to a close. I have been lax in posting blogs about our happenings here at Royal Master, but it is a positive that we have been extremely busy. We are closing out 2017 with an enormous amount of business. Both medical and non-medical parts of our business have been expanding rapidly. Our GX machine in its third generation has cemented itself as a highly productive production machine in many companies guidewire manufacturing facilities. With orders stretching out to June of next year for the GX machines, we have been pleased with the program.

Even years bring IMTS and an opportunity for us to showcase technology to existing and future customers. We enjoy this opportunity and even though it is hectic, our engineers look at it as a fun part of their job. We work really hard to bring you the best in automation as well as centerless grinding technology. Of the 8-10 machines that we have tentatively sketched out for the show, there will be a nice cross section of our product line for discussion.

We will also bringing out AMO 2.0. This have been a fun and successful project as customers worldwide. Customers enjoy keeping tabs on their production on their smart devices. On a recent plant tour one customer brought up his history laughing saying that the operator drinks his coffee like clockwork. It was a humorous moment for everyone in the room to say the least.

This year Royal Master added another Mazak machine a Smooth 250 Lathe, this is an awesome machine that has eliminated a bottleneck in our CNC turning area. In addition to this machine we have added 5 employees in key areas and also added a permanent Co-Op intern program.

Hiring Corporative Education Students from colleges that offer the program has brought us a great deal of satisfaction in paying our knowledge about the industry and life forward. The employees here all take a great deal of pride in their jobs and this company and enjoy teaching their respective jobs to someone willing to learn. Using the Rochester Institute of Technology COOP Program, we have had a number of men and women come through for 3-6 month stints over the last couple of years. All have kept in contact with us giving us updates to their personal and professional accomplishments.

For those who have ...

The end of another year is here

It has been an amazing year and 2016 is coming to a close. All of us at Royal Master Grinders want to thank you for your business and the opportunity to work with your companies each and every day. We understand and don’t take lightly the trust you put in our company, to grow yours.

We have had some great things happen this year. We have had continued success with our TG-12×8 machine, and IMTS reaffirmed that it is a proven winner two years since its debut. With a number of orders for machines at IMTS, we were proud to also sell a few of these machines at the show for deliveries in the coming year.

MDM in California and IMTS and were awesome shows with a large number of qualified attendees coming to our booth and working with our engineers on existing and new projects. For Rich, Bob and myself all the hard work we put into these shows, it is very gratifying to see the results of that work turn into viable projects for the coming years.

One package includes full CNC dressing and enclosure for shipment abroad. This will be an amazing machine that we will bring you along for the ride with as it is being built. The granite has arrived and soon will be married to the base.

This year as we do every year we introduced a new product. It was not a centerless grinder, but it was an App for your mobile device. AMO, or Advanced Machine Optimization in its very basic form is the production whiteboard at your fingertips. For use on IOS, Android, or Windows devices, you can log into your machine’s production data in the cloud and view its performance at any time. Different from MTconnect in many ways, this is a method of determining how to optimize your machine’s performance levels on your given application. For example, if your running three shifts and you are getting 30% less output overnight, Bu analyzing the app’s historical data in excel, it is quickly evident that the guy is taking long dinner breaks, or letting the machine sit idle for various reasons. Call us and ask for a test drive of this powerful tool.

From all the employees at Royal Master, we want ...

Day two in the books at IMTS set-up

Rich and I are sitting here eating a pizza tonight checking e-mails and I figured I would catch you to speed on what we did at work today…. See the attached you tube video!

Day three is all about powering up the machines and making spindles turn!

Thanks for reading

John

Olivia the intern’s Blog Post

For those whom have been reading this blog for a few show cycles, I have had interns the summer of IMTS, Olivia our third in 8 show cycles. She is a Senior at TCNJ, here in NJ. She has taken my instructions at the beginning of the summer and executed them flawlessly. Here is her blog post that I asked her to write at the end of the summer:

When I started my first day at Royal Master Grinders, I was as nervous as anyone else starting a new job. I remember being very timid in this new place surrounded by new people that had already been here for years and here I was, the college intern who didn’t know anyone’s names or what to do. Looking back, boy do I feel silly that I was ever scared. Within a few short days, I could already feel this work family accepting me as their own. John Jr. threw me right into the work atmosphere and there was never a dull moment. Working mainly with the upcoming IMTS details, I quickly learned more than I ever thought possible. Not only did I learn about the makings of a great trade show exhibit, but also the extreme precision and hard work that everyone in this office exhibits to keep things running smoothly. I think one of my greatest lessons was learning the true qualities it takes to be a leader. This does not mean someone who barks orders and hangs back from the real work. A leader is someone who is involved in every aspect of their projects. A leader is someone who knows how to take command and gain the respect of all of their employees. A leader is, most importantly, someone who genuinely and whole-heartedly cares about their work and all of those who are involved in it. These were the qualities I saw every day at Royal Master Grinders.

Unfortunately, I have to return back to school before I can truly see the outcome of the intense work that has been put into IMTS. I was most looking forward to seeing the loading of the huge truck to be shipped to the show! For anyone that is even remotely familiar with the Royal Master Grinders work family knows how hard of a goodbye this will be for me. From Stacy singing everything she does, to Bob’s never-ending witty comments, ...