Supporting Our Customers Is A Key Priority.

Royal Master prides itself on custom engineering and creative solutions for some of the hardest centerless grinding challenges in the world. Some of the applications shown here are pedestrian, others are really interesting and challenging. Grinding under .001″ in diameter, or shaving .2 seconds off a cycle to net over 10,000 more parts a month, and infeed grinding 6 parts at a time. We embrace the challenges. Here are some of our projects that we have done in the past few years.

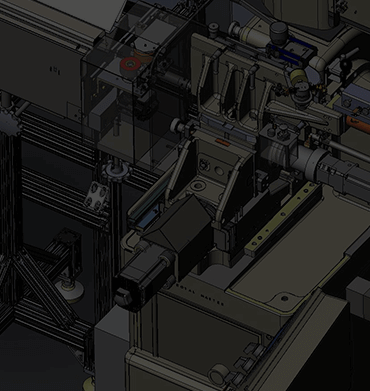

Thrufeed Titanium Bar Stock with a Custom Designed Automation Project

Thrufeed grind rods with auto load

Fluid Dispensing Nozzle Project With Full Automatic Loading, Unloading and Keyence Gauging

Infeed grind headed pin using robot load and unload

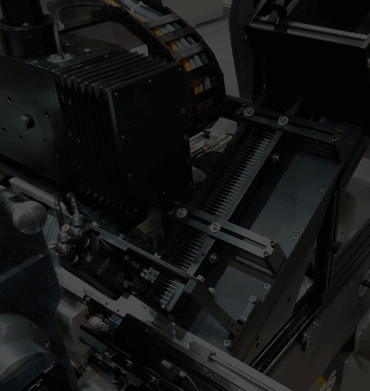

Diesel Injector Project with Magazine Part Loader and 7 Axis CNC Centerless Grinder

Infeed grind a fuel injector valve to close tolerance