Supporting Our Customers Is A Key Priority.

The TG series of machine have been grinding catheters for as long as anyone can remember here. When I discussed John Sr’s earliest memories of catheter grinding, he tells me the story of being at a Tradeshow in Detroit in the Mid 1960s and a Gentleman named Ralph and his Dr. colleague visited our booth. At the show we were grinding wire from .010” to .005” and their interest was piqued. They quickly asked John Sr to visit southern Florida to discuss their application. This was the beginning of the catheter and guidewire grinding business for Royal Master.

We tried to figure out how many Royal Master Machines around the world are grinding catheters and we figure 500+. It’s truly amazing, and offers us pause when we think of how many people’s lives we have been a part of due to that simple tradeshow interaction.

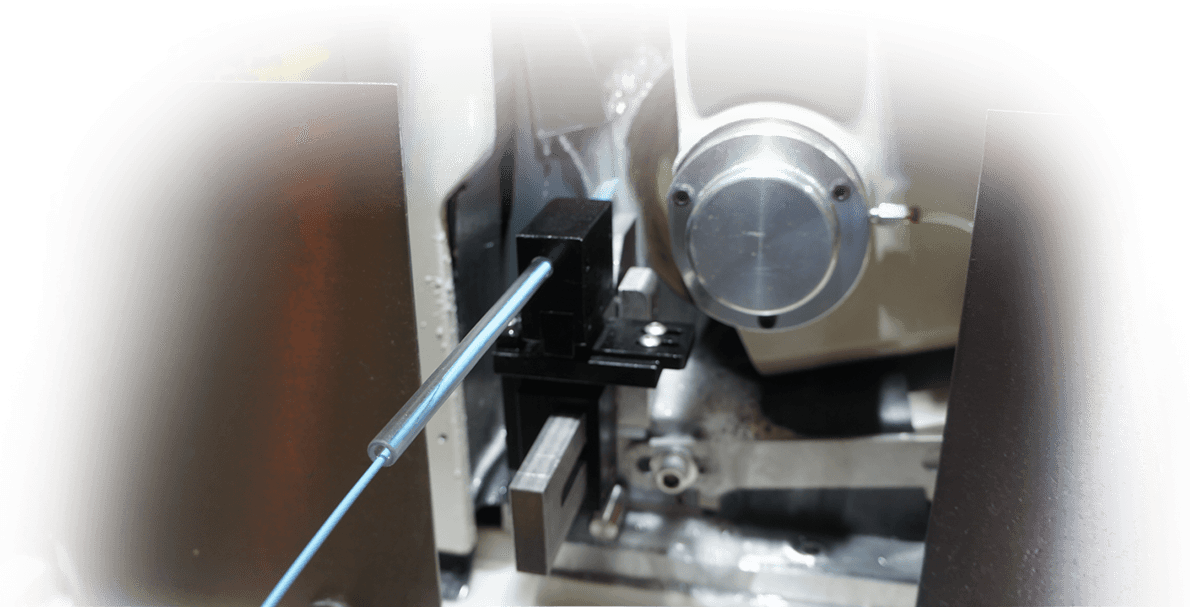

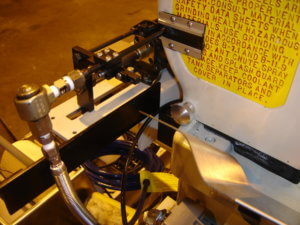

Since then the basic technology has stayed the same but the innovations have come in wheel technology as well as automation and wheel maintenance. Machines now can come with Stainless Steel packages, Pressurized wheel cleaners, and venturi systems for introduction and removal of catheters. Multi-grit wheels are common to grind Pebax as well as other materials unheard of 50 years ago.

GRINDING EXAMPLES

Other Wire Grinding Solutions

Catheter & Dialator Grinds

Billions of catheters ground since the 1960s

Needle Grinding System

1250 Trocar Needles Per Hour Production Rate Per Machine