Supporting Our Customers Is A Key Priority.

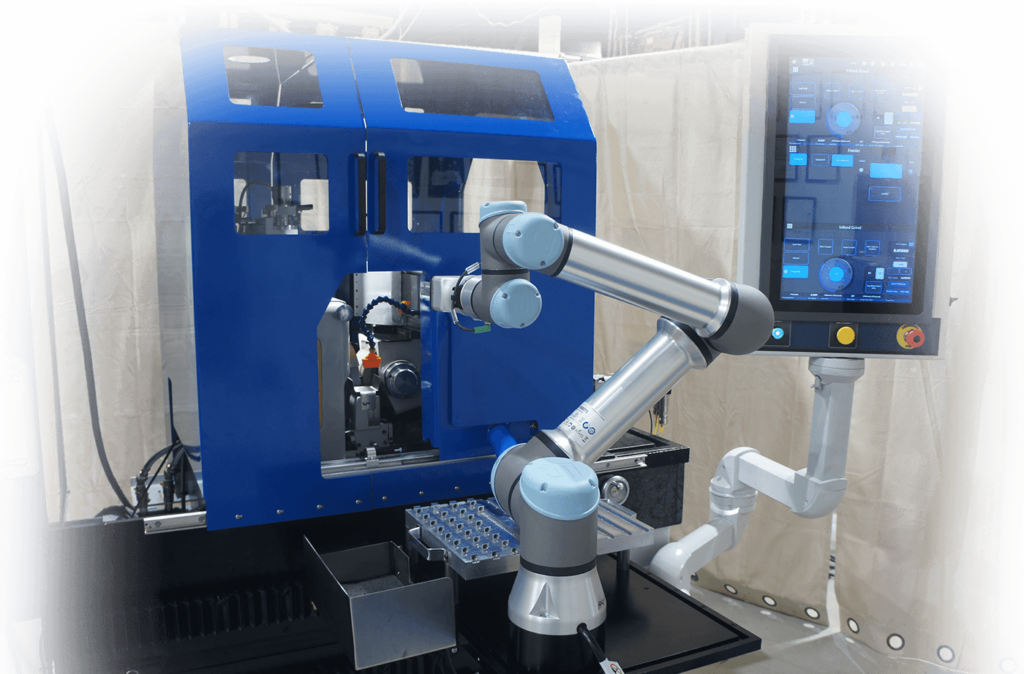

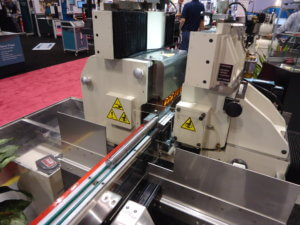

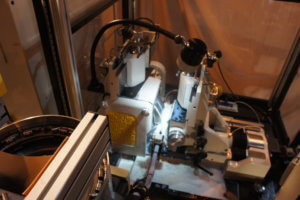

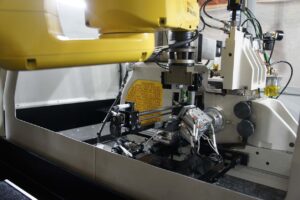

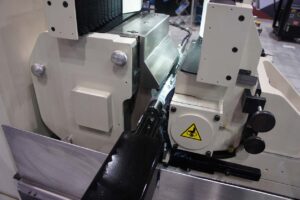

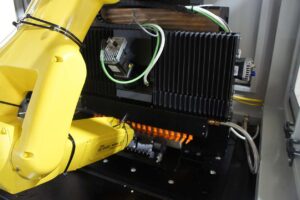

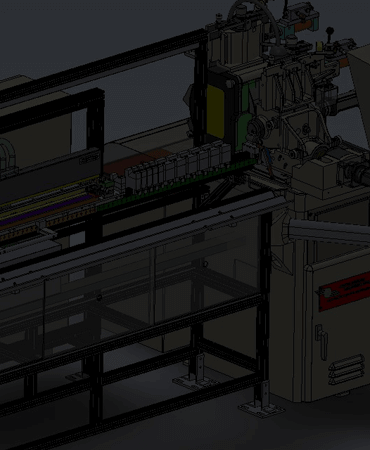

What is your goal when it comes to automation? It is not a one size fits all proposition. In some applications, a simple operator assist device is sufficient as the part quantity doesn’t merit a robot or pick and place. In other cases, an adaptive or non adaptive robot is the key to a successful project. Royal Master has done just about every kind of automation since 1950. Vibratory bowls, magazine feeders, pick and place, in line gauging, Universal and Fanuc Robots All of these projects have been implemented around the world. The best place to start this type of conversation is with a simple question from us, “what is your goal for automating your centerless grinder?”

Automation Videos

Want More ?

Other Wire Grinding Solutions

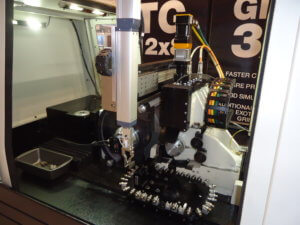

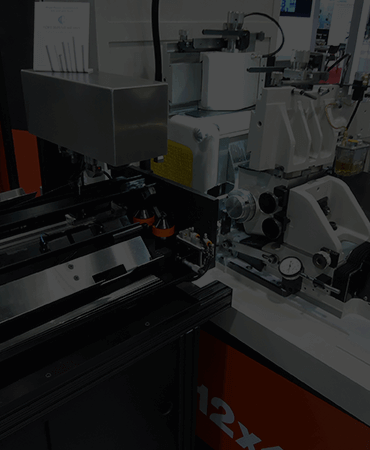

TG-12×4 and TG-12×8 Servo Cycle Grinding Systems

The most versatile machine for up to 5 taper wire grinding

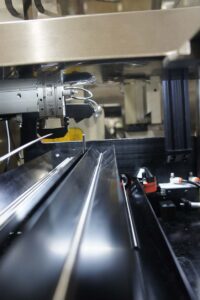

Automation of Guidewire Grinding

Operator Assist Devices to Fully Robotic Multitasking Solutions

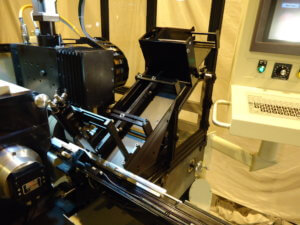

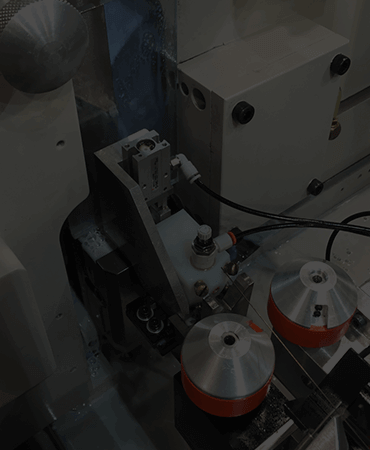

Generation 5.8 Production Guidewire Grinding System

The machine that revolutionized the wire grinding industry is still producing millions of wires per year worldwide