Supporting Our Customers Is A Key Priority.

T-21 Hours Until We Load

Many of you have called and talked with or e-mailed Alan Schell who is our main customer service representative here at Royal Master. We call him “world wide” mainly because he interacts with many different companies around the world effortlessly. Alan’s lineage at Royal Master began over 20 years ago as our Crib manager, from there into purchasing, then to customer service. He always approached his job with a smile and enthusiasm.

Alan and I go way back to when I was in high school and college working for him in shipping and receiving. Him and Mr. Mc Cracken were a good team and still today we often tell stories about Mr. Mc Cracken’s booming voice and crushing handshake. When Alan came out to ask a question this morning about a shipment going to Japan, he was quick to point out that we should put a little more shrink wrap around this machine before it loaded onto the flatbed tomorrow.

The answer to his suggestion is shown below.

T- 21 hours to we load.

A Little Fun with Dry Ice and a New Machine Enclosure

I do not think any explaination is needed. I think we had more fun with the Dry Ice when the camera was turned off.

Skidding machines, Sounds Simple Enough

Skidding machines, one of the most difficult jobs when it comes to IMTS. We call it packing ten pounds in a 5 pound bag. We have talked about in previous blog postings about the jigsaw puzzle that our truck is, but fitting everything on the skids is an art form. On the bigger projects like the bedrock we have the machine, JIC Cabinet and coolant filter. We fit all of that on a 64” x 96” skid. Nothing can hang off especially on the 96” dimension as it would hang off the side of the truck.

We keep all of our machines on the skids at the show. If you look at the show photos you will see that they are all on platforms, these are the skids, we pop off a tiled side and the forklift can just get under it and drive away. Easy. We do not need any spotting of machines which saves around $2500.00 in rigging costs on the inbound and outbound. It also saves a ton of time. The machines come off the truck, and get put right into the chalk line markings. Truck to booth and spotted, less than 5 minutes per machine

On Saturday we skidded all of our machines, plus packed a few other Miscellaneous Skids for Saturdays ship date. With the Help of 6 guys this is the equivalent of asking your buddies to help you move for the 12th time in a year. Not a fun job, but it has to get done. During the course of the morning we found a few things:

- A misplaced cross beam means we get out the Herman Munster Homemade Sledge Hammer ( 4×4 Steel block Welded to a 4’ long pipe) to put another cross beam into the skid.

- It is possible to get stuck under a skid trying to put a bolt in. I will forever think I was set-up for the photo that is shown here. They had to pull me out by the feet.

- Sometimes the best laid plans and autocad layouts just do not work out as originally planned.

- Bedrock + Coolant and Filter+ Electrical Cabinet = more that a 5,000 lift can handle. Solution: Machine bed counterweights. Number needed … 8 to keep the back wheels of the forklift on the ground.

By 1:00 we were all pooped and happy its finished. Un-skidding them happens September 25th come join the fun if you ...

With two weeks to go before shipping a lot is going to happen. The basic plan in place for this week is to get all the machines finalized and running, then on Saturday everything is to be re-skidded onto their pallets. In our booth we leave the machines on their pallets and make them look nice. It is less expensive to do it that way and to be blunt no one really ever notices or says anything.

I am fortunate that I am Involved in the Association for Manufacturing Technology. This trade association is not only instrumental in the production of IMTS, but they have an arm that looks out for Manufacturing’s best interests in Washington. Some of the Tax cuts that aided machine tool builders in the past 10 years were lobbied for by this association.

As part of AMT on Thursday I went to Chicago for a final meeting to review the show with 8 other exhibitors. We all have been around the trade show world for many years now and we range from large companies like Haas to companies like ourselves. Our goal is to give a voice to the exhibitors and help the direction of the show from a behind the scenes. During our visit to GES we saw a lot of the ideas we discussed for two years come to life. It should be a really good show with can’t miss Keynote speakers, and a really cool Emerging Technology Pavilion. Lockheed Martin will have a Fighter Jet on the floor also in the West Building

From concept to reality, we have been talking about the Bedrock series for a while now. This new machine platform besides being really cool looking offers a ton of advantages for production grinding. You can see that the machine is done and is getting tooled out for the show this week also. In about a week you can visit our web site booth6646.com for videos of all our machines in our booth.

If you cannot come to IMTS 2010 this website will give you the same experience as if you were in Chicago . Once the machines are on site we will re-take the videos for all to see the parts grinding , and the booth up and running. Until then ...

Bedrock is Done

Wednesday of this week serves as our first customer demonstration for our NEW bedrock series of centerless grinders. One of the first blogs that was written included a photo of the machine’s bed being machined at Rock of Ages in Vermont. Now the design has come to life and is a machine tool that is grinding applications to under .000010” roundness.

After our demonstration on Wednesday for a customer we will be starting to tool out the machine for IMTS. Outside of the machines new design, and superior accuracy we will have some other pretty cool accessories on it.

- New Magazine Feeder design that is easier to load parts into a hopper for longer unattended operation

- In corporation with Laser Linc we will have integrated into the machine a new LobexTM Lobing Detection System. It performs real-time analysis of centerless ground products to detect and report a constant diameter but out-of-round condition due to lobing of any frequency (e.g. 3, 5, 7, 9…).

- A full machine enclosure that gives full access to the machine from any angle

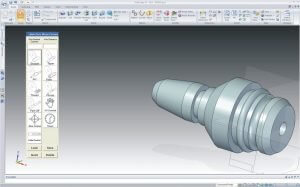

- New Software features for programming in virtual templates for CNC Dressing. This integrated system enables you to design your part or template on the machine’s interface. This tool also interfaces with your engineering software to bring the solid model on-board to your centerless grinder. From there it generates the Excel worksheet which will either dress your wheel or grind your part without ever seeing a G or M code.

We thought of everything, including a tool tray on an articulated arm that will keep your machine neat and clean, multiple language support, Internet connectivity for lights out grinding, and even a utility that can have the machine e-mail machine production statistics at a hourly frequency.

All of this adds up to pretty cool new machine.

Instant Information

On Sunday I arrived at the beginning of my journey to Asia: Newark Airport. With a sigh I got off the monorail at Terminal A, rather than my usual stop at Terminal C. This was only because the usual direct flight that I take was all booked and so our illustrious Lori got me on a partner airline, United. The only issue was instead of a direct flight, I had to connect through ORD (O Hare). This added another 3 hours to the travel time, but with 13 hours vs 16 hours, at that point you’re numb and hungry anyway. While sitting in the lounge (a perk of the Continental / United merger) an announcement began saying my EWR to ORD flight was cancelled. Looking at the time, I started to formulate a Plan B.

I walk up to the counter at the lounge, and politely say I really need to get to Asia but my flight is cancelled, and the next EWR to ORD will not get me to Chicago in time for my connection, what now?

to ORD will not get me to Chicago in time for my connection, what now?

A few clicks and a few squints at her screen, and she produces a boarding pass that is famous in Royal Master Circles – “The Express”. This was my original preference before I was booked on United, but the cost was insane. As soon as I figure out what happened and realize that I was treated to a direct flight, my phone beeps and buzzes stating that my new gate of departure is 121 in Terminal C. Continental instantly sent me an update to my status of my gate and departure time.

Frequent flyers have all experienced this instant information but in the information age what made this cool is with a simple Mobile phone number or e-mail address, all of this is instant. Back when instant coffee was an innovation, it was coffee made fast, but now it takes too long for water to boil on a stove. So we look for faster ways to get hot water.

Instant information is key to running high volume production. Every minute of lost production means lost profits. Royal Master has now incorporated in their machines the ability for the machine to e-mail up to 10 addresses or send out text messages to mobile phones numbers when a ...