Supporting Our Customers Is A Key Priority.

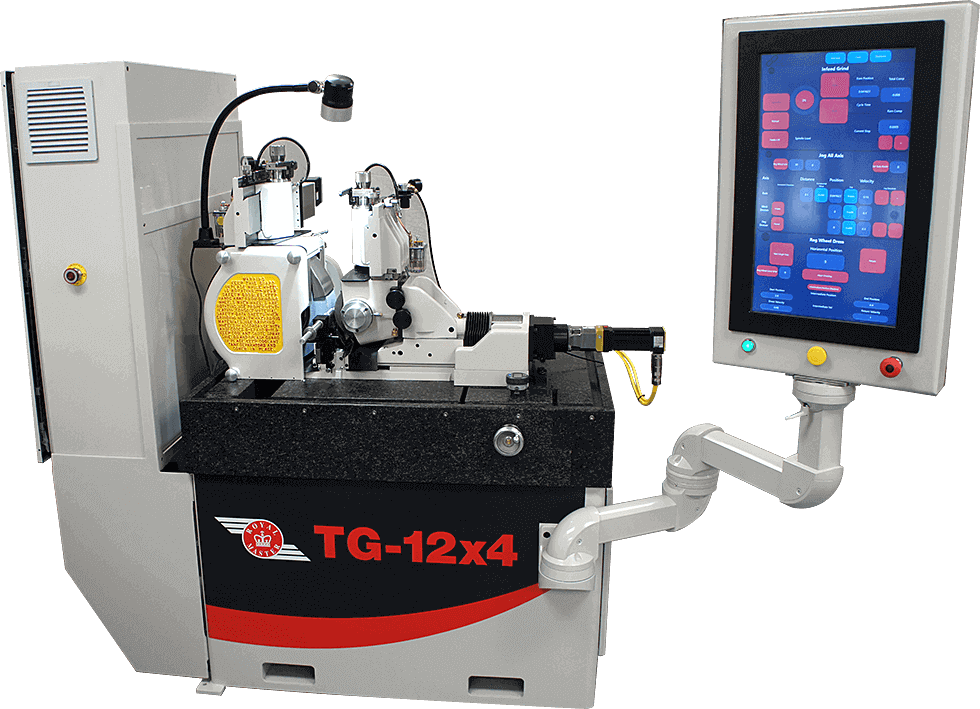

Since 1950, family-owned and operated Royal Master Grinders has proudly provided customers with centerless grinding systems. We manufacture machines with varying levels of complexity, offering solutions that range from basic to highly intricate. Our application engineers understand that there is no one-size-fits-all solution, addressing thousands of unique applications over seven decades.

With over 225 years of combined centerless grinding experience, we offer a wealth of knowledge to discuss your application. At Royal Master Grinders, we build centerless grinders because we love the challenge each new application presents. Whether it's cycle time savings, helping a company win a contract, boosting profitability, or producing life-saving medical devices, our 65-person team makes a significant impact worldwide. We take this responsibility seriously.

When customers present new applications, we value and respect the opportunity to engage with them. We understand that 0.5 seconds of cycle time can make the difference between winning or losing a contract. However, at Royal Master, we never overpromise on cycle times or tolerances.

Since 1950, a common scene in many shops worldwide has been an operator handloading parts into the machine, day in and day out. Customers have approached us to automate various applications, each unique. Some seek simple solutions, while others require fully robotic systems. The goal is always the same: repeatable and predictable cycle times without operator intervention.

This philosophy led us to develop AMO (Advanced Machine Optimization), a unique tool from Royal Master. The AMO app provides straightforward insights into your machine's performance on your mobile device, enabling you to optimize your system efficiently.

Our favorite story after implementing AMO comes from a European customer who discovered that their operators were shutting off the machine during lunch breaks. By studying the data and machine performance, they realized they could produce an additional 270 parts per day. The data showed that the machine could run parts, automatically compensate, and stay within tolerances without supervision. AMO also recommends maintenance intervals and provides other critical data to help increase your production output.