Supporting Our Customers Is A Key Priority.

Our first high accuracy system came about in the 1960’s with a Marposs controller and a first in the industry. When I asked John Memmelaar Sr. the lead engineer on this project he reminisces about holding .0001” with a micrometer as the standard. This was a tight tolerance on the crown roller bearing application. Now our High accuracy system has certainly evolved as well as the tolerance capabilities. Back in 1960 .0001” was as challenging as a half a micron is today. We met the tolerance back then and we certainly meet it now.

Our TG-12x4 Hi-Accuracy system is a homogeneous centerless grinding system that boasts the best accuracy of any platform worldwide in this size range. The 12” (300mm) diameter and 4” 100mm wide wheel gives an ideal envelope for thousands of applications that have been presented to it.

Our TG-12x4 Hi-Accuracy system is a homogeneous centerless grinding system that boasts the best accuracy of any platform worldwide in this size range. The 12” (300mm) diameter and 4” 100mm wide wheel gives an ideal envelope for thousands of applications that have been presented to it.

The Hi-Accuracy system is available in various configurations, from basic cost conscious to the bedrock series which can be equipped with up to 8 axis of CNC. These systems are used worldwide for grinding XXX Gauge pins to automotive applications where one German customer is at 23,000,000 cycles without a significant rebuild. That is one part every 8.3 seconds, 24 hours a day, 6 days a week.

If you were to ask us “when do we choose a Hi-Accuracy machine?” Our answer would be the following:

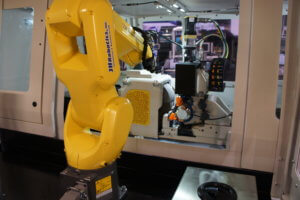

Our recommendation for the Hi-Accuracy is based on the grinding extreme close tolerance grinding of multiple diameters and transitions. Our next question is if post process gauging with feedback to the system making it closed loop is a consideration, as well as a high degree of automation including robotics. If you answer is yes to any or all of the above we recommend this system.

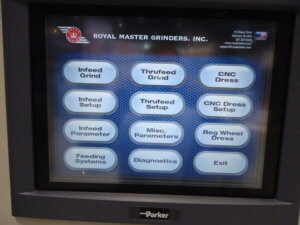

We offer this system from basic Hi-Accuracy systems that don’t use granite and are a basic two axis system. They still have our .1micron glass scale and accurate ram movements 2.5x the scale resolution regardless of options, all or All Hi-Acc machines make accurate ram movements in .000010” incrementations. The ram bed position control is our high accuracy frictionless cross roller way with ball screw and servo motor movement. The HMI is 17-inch touch screen with all machine function controls. The Windows base programming is remote accessible for data report sending and diagnostic connectivity.

The wheel spindles are supported by class 7 ABEC angular contact ball bearings. This high quality rigid spindle support design yields long life with superior roundness and size control. We offer an outboard bearing support for a twin grip design as an option.

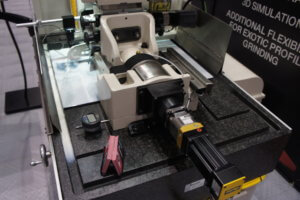

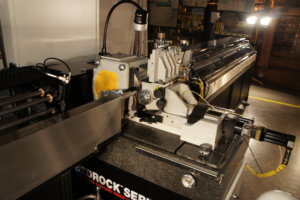

The machine sits on our BEDROCK Series, 8-inch thick granite with deep and wide machined coolant troughways. Rigidity and thermal stability are the benefit of this granite bed.

One of our most popular configurations is the TG-12x4 centerless grinder with full CNC Wheel Dressing on both work wheel and regulating wheel, CNC Ram Bed Position Control, speed control of the grinding wheel with frequency invertor, multiple language screen displays available, internet connectivity for remote access, feedback from gauge systems for automatic adjustments, BEDROCK machine bed, full enclosure with automatic and safety interlocked doors.

All Hi-Accuracy systems have the ability to take advantage of the Advanced Machine Optimization (A.M.O.) cloud database. By activating the AMO feature on your Royal Master your grinder will start to report machine specific information to our secure cloud database. Receive up to date reports of how your machine is performing and have the app remind you of your PM based on time of use. Check error logs, part counts, cycle times, part numbers and more. With AMO, you can stay connected to your grinding process and receive up to date information to optimize your manufacturing process.

We have partnered with companies such as Greymills coolant filtration, Losma Air Filtration, Cognex, Universal Robots, Fanuc, Keyence, SBS Dynamic Wheel Balancer with Acoustic Emission Gap Elimination and Analysis Tool. All of our partners have been an integral part of making custom systems for a variety of applications presented to us.

Specifications and

standard features

| Machine Capacity | .002” to 1.5” (.05mm to 38mm) |

| Accuracy | .00002” (.0005mm) |

| Sizing Increments | .000010” (.00025mm) |

| Grinding Wheel | 12” diameter x 4” wide (304mm x 100mm) |

| Regulating Wheel | 6” diameter x 4” wide (152mm x 100mm) Servo Driven 0-500 rpm |

| Spindle Power | 7.5hp (optional 10hp) Spindle inverters available |

| Weight | 2800 lbs non Granite, 3800 Granite |

| Dressers | Air Sensing, Permanently Mounted, stepping motor traversed with touch screen controls, Automatic Dressing system, CNC Over the Wheel, CNC Rotary Diamond Disk |

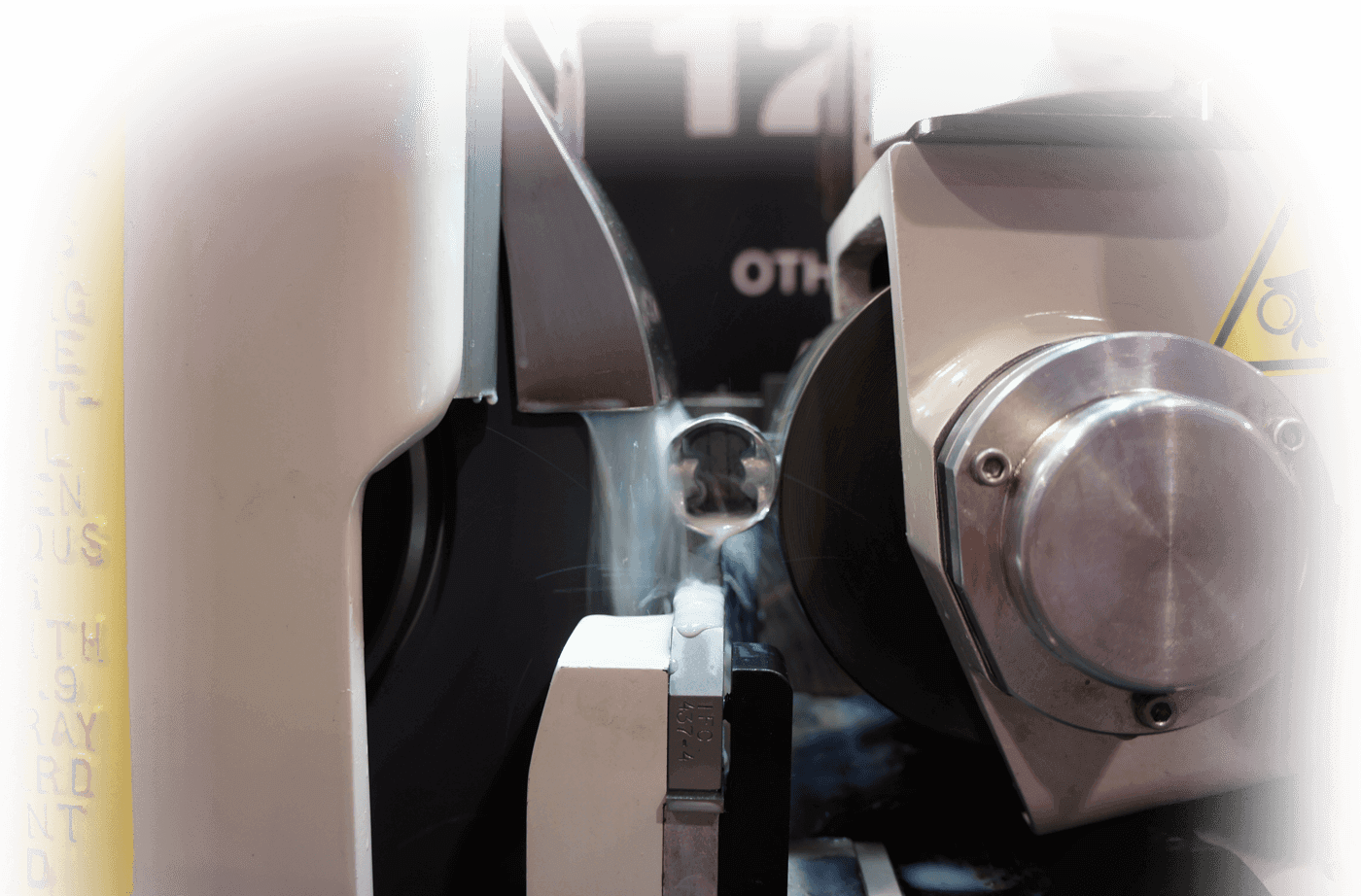

The TG-12x4 in action

Other Non-Medical 12x4 Solutions

TG-12×4 Infeed / Thrufeed Servo Cycle

Programmable Infeed / Thrufeed Grinding Ideal for a Job Shop Environment