Supporting Our Customers Is A Key Priority.

With two weeks to go before shipping a lot is going to happen. The basic plan in place for this week is to get all the machines finalized and running, then on Saturday everything is to be re-skidded onto their pallets. In our booth we leave the machines on their pallets and make them look nice. It is less expensive to do it that way and to be blunt no one really ever notices or says anything.

I am fortunate that I am Involved in the Association for Manufacturing Technology. This trade association is not only instrumental in the production of IMTS, but they have an arm that looks out for Manufacturing’s best interests in Washington. Some of the Tax cuts that aided machine tool builders in the past 10 years were lobbied for by this association.

As part of AMT on Thursday I went to Chicago for a final meeting to review the show with 8 other exhibitors. We all have been around the trade show world for many years now and we range from large companies like Haas to companies like ourselves. Our goal is to give a voice to the exhibitors and help the direction of the show from a behind the scenes. During our visit to GES we saw a lot of the ideas we discussed for two years come to life. It should be a really good show with can’t miss Keynote speakers, and a really cool Emerging Technology Pavilion. Lockheed Martin will have a Fighter Jet on the floor also in the West Building

From concept to reality, we have been talking about the Bedrock series for a while now. This new machine platform besides being really cool looking offers a ton of advantages for production grinding. You can see that the machine is done and is getting tooled out for the show this week also. In about a week you can visit our web site booth6646.com for videos of all our machines in our booth.

If you cannot come to IMTS 2010 this website will give you the same experience as if you were in Chicago . Once the machines are on site we will re-take the videos for all to see the parts grinding , and the booth up and running. Until then ...

Bedrock is Done

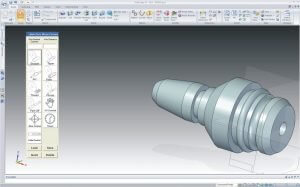

Wednesday of this week serves as our first customer demonstration for our NEW bedrock series of centerless grinders. One of the first blogs that was written included a photo of the machine’s bed being machined at Rock of Ages in Vermont. Now the design has come to life and is a machine tool that is grinding applications to under .000010” roundness.

After our demonstration on Wednesday for a customer we will be starting to tool out the machine for IMTS. Outside of the machines new design, and superior accuracy we will have some other pretty cool accessories on it.

- New Magazine Feeder design that is easier to load parts into a hopper for longer unattended operation

- In corporation with Laser Linc we will have integrated into the machine a new LobexTM Lobing Detection System. It performs real-time analysis of centerless ground products to detect and report a constant diameter but out-of-round condition due to lobing of any frequency (e.g. 3, 5, 7, 9…).

- A full machine enclosure that gives full access to the machine from any angle

- New Software features for programming in virtual templates for CNC Dressing. This integrated system enables you to design your part or template on the machine’s interface. This tool also interfaces with your engineering software to bring the solid model on-board to your centerless grinder. From there it generates the Excel worksheet which will either dress your wheel or grind your part without ever seeing a G or M code.

We thought of everything, including a tool tray on an articulated arm that will keep your machine neat and clean, multiple language support, Internet connectivity for lights out grinding, and even a utility that can have the machine e-mail machine production statistics at a hourly frequency.

All of this adds up to pretty cool new machine.