Supporting Our Customers Is A Key Priority.

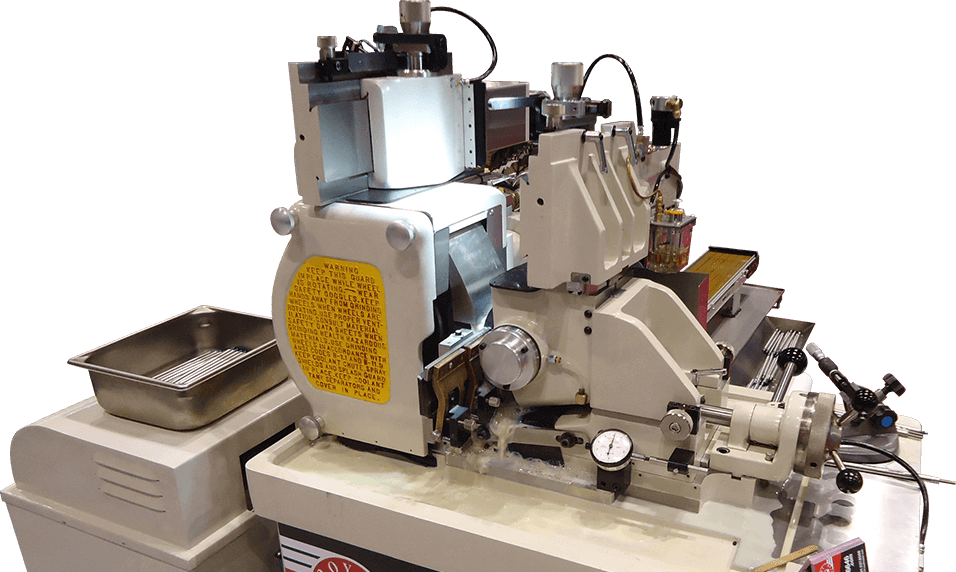

The TG-12x4 and TG-12x8 "Thrufeed and Yank Method" was the first method of grinding wires in that the operator would introduce a wire blank to the wheels which were pre-formed with the necessary taper by template dressing. When the back of the wire crossed a witness line, it would be pulled out by the operator. To this day, many new and established companies grind wires this way. You can grind as fast as you can load. Material is not a concern for this type of equipment—Grind Stainless Steel or NiTi without difficulty.

This method of grinding is utilized when the taper length is less than the wheel width. In the case of the TG-12x4 it is 4” (100mm). For the TG-12x8 it is 8” (200mm) wide. It is a very simple method of grinding, and when using the right method of loading and unloading it can be very fast. See the below video for a single taper grind using a servo cycle machine. We are using a Royal Master Feeder and part to part cycle time is less than 9 seconds.

Over many years the available accessories have gown for grinding guidewires. Simple accessories that are available are outboard supports, simple eye activated retraction devices, blade sizing devices that can be moved from machine to machine, and various types of automation.

For a more complete equipment description please click here to read about the TG-12x4 basic thrufeed.

TG-12x4 SIMPLE WIRE GRINDING

Other Wire Grinding Solutions

TG-12×4 and TG-12×8 Servo Cycle Grinding Systems

The most versatile machine for up to 5 taper wire grinding

Automation of Guidewire Grinding

Operator Assist Devices to Fully Robotic Multitasking Solutions

Generation 5.8 Production Guidewire Grinding System

The machine that revolutionized the wire grinding industry is still producing millions of wires per year worldwide