Supporting Our Customers Is A Key Priority.

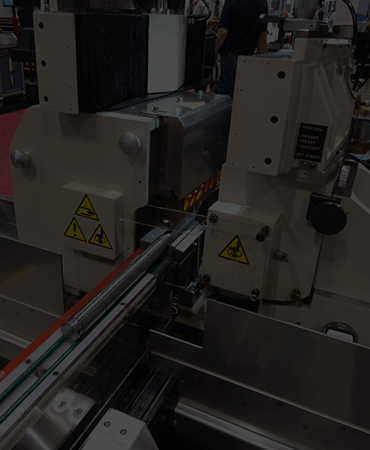

The TG-12x8 Servo Cycle has an enormous amount of flexibility to do infeed and Thrufeed grinding from .002” to 3” in Diameter. Its two axis of CNC control with its user-friendly touch screen make centerless grinding simple and straightforward. This clean machine design makes for an attractive system that is highly accurate and versatile. One look at this machine is all that’s required to determine

The servo cycle machine was first introduced with our TG-12x4. With that systems popularity it was only natural to make it a staple of our TG-12x8 product line. The system uses a 10” touchscreen control with the Parker PAC control. This combination makes for simple user interaction with repeatability to well under .0001” (.0025mm)

The Servo cycle system is a perfect fit in-between a standard Thrufeed machine and a HI-Accuracy machine. Its dovetail and gib system with turcite ways give less than 2 micron repeatability while still maintaining the standard 1 micron round and straight capabilities.

The user friendly 10” HMI control gives the operator the capability to easily navigate machine functions at your fingertips. Thrufeed grinding gives you the ability to match a gauge for easy compensations. Infeed grinding is where the servo cycle sees the biggest advantage. Programmable rates and distances for your infeed cycle makes operation easy. Programmable load positions for you part as well as grinding zones makes full control of your part grind simple. Save all your programs resident in the control for future recall.

The TG-12x8 offers a grinding wheel diameter of 12” (300mm), a regulating wheel of 8” (203mm) diameter, both being 8” (203mm) wide. The advantage is clear, wider wheels allow for heavier stock removal for thrufeed grinding. Standard out of the box is a granite machine bed that allows for a more stable platform and a machine with a higher degree of accuracy.

The grinding wheel spindle design has 4” (100mm) diameter bearings, with three sets of class 7 ABEC angular contact Timken bearings. It is inside a larger headstock with an outboard bearing for a twin grip design. This design gives the grinding wheel superior accuracy. When mounting diamond wheels on machines with an 8” wide wheel, a outboard bearing is critical so there is no spindle deflection.

The regulating wheel with its 2.25” (57mm) spindle and Timken bearings allows for the most demanding applications to be ground with zero deflection of other machines with smaller spindle designs.

Standard on our TG-12x8 is servo driven regulating wheel spindle with 170 foot pounds of continuous torque, and a 10:1 gearbox. We also added stepper drives for programmable traverse rates and ball screws to our dressers as standard equipment.

Ram bed positioning has also been upgraded with a longer and wider ram bed. The upper ram, utilizes hard chrome and Turcite for the most efficient and accurate movements. With the servo cycle ram movement the operator interfaces with a touchscreen. Jogging the machine, making finite diameter changes is easy and straightforward. With its built in part library, parts are saved and can be easily recalled.

Any application can be thrown at this machine, automotive, cutting tools, aerospace fasteners, low or high volume, this machine is designed with a high degree of accuracy and longevity for your company.

Specifications and

standard features

| Specifications | |

|---|---|

| Machine Capacity | .002” to 3.0” (.05mm to 76mm) |

| Accuracy | .00004” (.001mm) |

| Sizing Increments | .00004” (1 Micron) |

| Grinding Wheel | 12” diameter x 8” wide (304mm x 200mm) |

| Regulating Wheel | 8” diameter x 8” wide (200mm x 200mm) Servo Driven 0-500 rpm |

| Spindle Power | 10hp (optional 15hp) Spindle inverters available |

| Weight | 3800 lbs |

| Enclosure Options | Multiple options available depending on customer requirements |

| Dressers | Air Sensing, Permanently Mounted, stepping motor traversed with touch screen controls. (Programmable Dual dressing zones standard) Optional Automatic Dressing using templates |

THE TG-12x8 SERVO CYCLE

OTHER NON-MEDICAL TG-12x8 SOLUTIONS

Ball Grinding System

Grind up to six 1.4” balls in less than 10 seconds

TG-12×8 Hi-Accuracy Centerless Grinding System

Centerless Grinding System for the Most Demanding Applications