Supporting Our Customers Is A Key Priority.

Day One of Set-up and The Truck That Was Just Long Enough

we loaded up the truck and it was just long enough. We had to squeeze everything together to make sure it all fit, however we had three inches to spare.

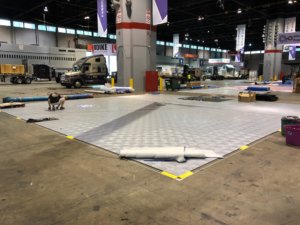

Day one is done setting up the show, nothing crazy other then laying the floor and chalking out the machines to ensure we like the layout.

Tonight’s dinner will be the Purple Pig. Great food and better atmosphere.

https://thepurplepigchicago.com/menu/

Tomorrow we welcome in Alex and Oscar into the set-up mix. Oscar is a first time IMTS guy so he will be donning the pink bicycle helmet before he leaves.

Meet Alex the Intern!

As in past years we hire an intern for the summer. We ask our intern’s to summarize their experiences at the end of the summer and this is her’s. Also as a rite of passage it is a requirement that she drives the forklift……….

ALEX’S BLOG POST

Wow, where to begin.

I would have never thought when I started here at RMG that I would learn as much as I did this summer. I can honestly say that it is one of the best environments I have ever worked in. I will leave here not only having learned so much about IMTS, but also having learned a lot about how important it is to work fluidly as a team and to have fun no matter what you’re doing. This is a family that I feel very lucky to have been a part of this summer, and I think any other intern that has the opportunity to work here would say the same thing.

Day 1: I walked in completely blind not knowing what this place even did or what would be expected of me. I had never worked in a machine shop before. I was paired with Michele to do inventory and immediately loved her energy. She was smart and funny and had this great vibe, and I knew right away I was going to like it here. Counting hundreds of little metal parts could quickly become tedious, but she didn’t make it feel that way. In fact, everybody here knows how to make the best of what they’re doing, usually by making sarcastic jokes. (Or if you’re Alan or Stacy, by singing.)

That morning, I saw a very tall man running around all over the place giving direction and joking around with everyone. It was John, the boss; the man in charge. Not knowing him yet, I was intimidated a bit at first and now I know I couldn’t have been more wrong. John is one of the most generous, kind, caring bosses I have ever had, and I have had my fair share of jobs. He is extremely easy to talk to and made the process of learning something completely new easy, even though his favorite thing to do when I have a question is to run away and pretend he doesn’t see ...

Three days until we ship a lot of machines to IMTS 2018

There is 4 days to go until we do the packing of the truck. For those who are new to following my blog, it is a day that is filled with a lot of satisfaction. All of us at Royal Master have worked for 9 months to get to this day. We welcome the truck into the lot and when it leaves, we exhale. Rich and I split the show up into three sections, the 9 months of prep, “the show” and then the “after show”. The actual show is enjoyable for me, and it is the least amount of stress. I love talking to the people that come into the booth discussing the different projects that we are presenting, and past projects that are applicable to their particular application.

We are fortunate that our team at Royal Master is fully invested into he success of our company at the show. There are a lot of late hours, and people asked to do jobs that they normally don’t do, but the results speak for themselves. We are happy to share the results with our employees as they were a large part of the success of the show for us.

We are introducing our GX3 machine at the show. Its dual grinding wheel set-up allows for applications such as endodontic files be ground in 1/3 the cycle time of conventional systems. Its primary grinding wheel creates the initial part of the file, and then the secondary wheel creates the flutes in the part. Its pretty cool! The machine cones with a completely new look enclosure which makes the system look sleek and modern.

Our New Hi-Acc machine has a new operator interface. The 24” touchscreen interacts in a new way with the operator where as multiple screens can be open at one time making navigation easier. There is total customization for each operators preferences. Just like a memory seat in a car but for machine tools.

Of course will have a robotically loaded machine, Fanuc and Keyence are strategic partners on this project . We will also have a TG-12×8 thrufeed machine grinding 8000 parts per hour feedrate. You must stop by to see how we are doing this! In addition to all of this we have a lot of variety in equipment. Simple Thrufeed machines to highly automated systems. Our machines are not one size fits all propositions.

what happens when you bring your kids ...