Supporting Our Customers Is A Key Priority.

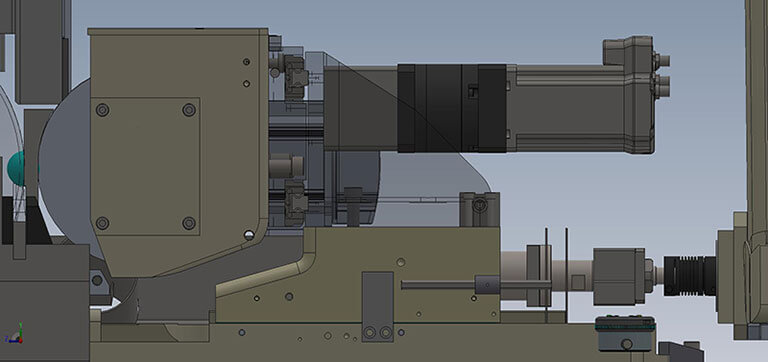

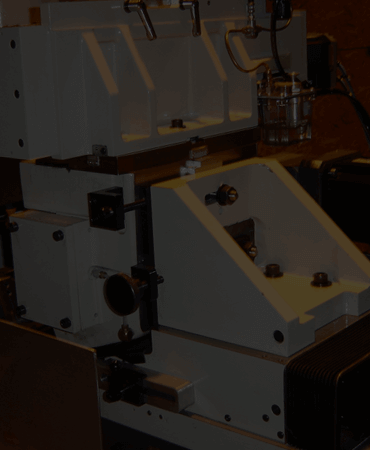

Royal Master has developed a ball grinding system from the ground up using our Robust TG-12x8 platform. Built for longevity and with the latest in operator interface and standard servo driven axis, this refreshing entry into the ball grinding market is quickly becoming popular. What makes this entry so different is that the infeed motion of the regulating wheel is servo controlled allowing for operator to tailor their infeed parameters with a rapid take up – coarse grind – fine grind – spark out program. All is applied to the machine with calculator inputs. The result is cycle time savings as well as all the benefits of system without hydraulics.

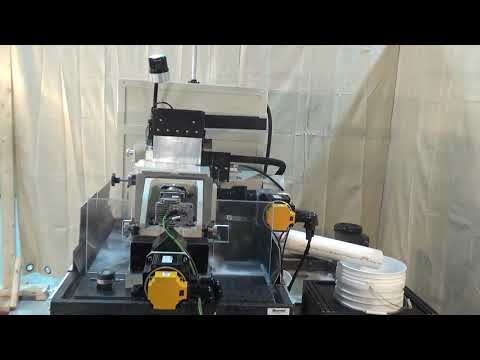

We are grinding 5 plastic injection molded balls in 8 seconds with no operator handling. That is a net of 7,200 balls per hour.

Royal Master Grinders has developed a system to automatically load, grind and unload spherical balls without operator intervention. Virtually all materials can be ground, including Polypropylene plastic, Teflon® (PTFE), rubber, wood, glass, and ceramics. Cycle times will vary with the application. Sphericity and size tolerances will vary with the application.

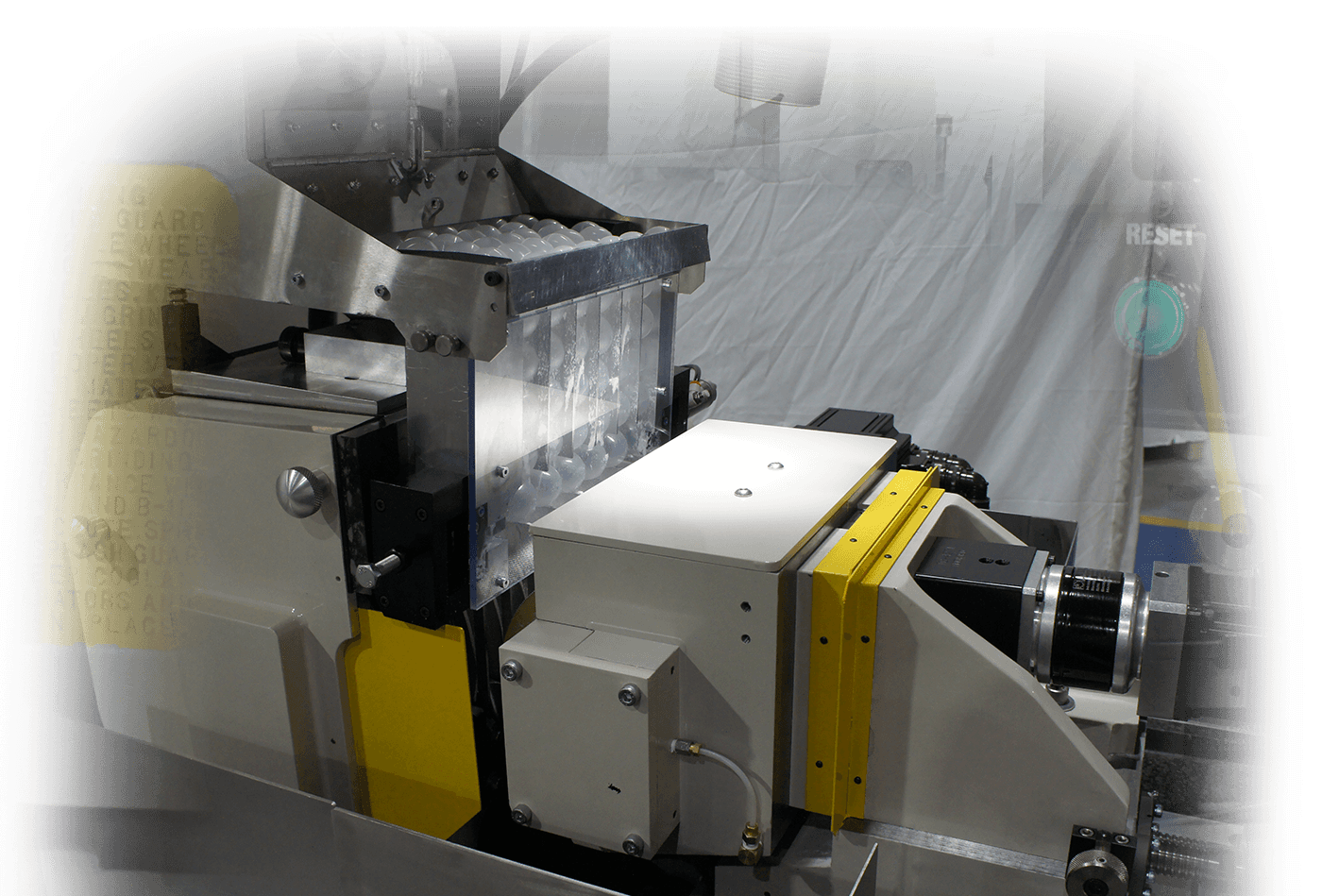

Using a grinding wheel 12 inches in diameter and 8 inches wide, we design the wheel form to the contour of the spherical shape and fill as many positions across the 8-inch-wide wheel as will fit. This application has 5 balls, each 35.5mm in diameter.

The regulating wheel is 8 inches in diameter and 8 inches wide. It rotates at an RPM to control the rotational speed of the balls. It oscillates to keep the ball moving off axis and create a true sphere. The infeed grind rate is very fast to result in the load, grind and unload in 8 seconds for this application. One of the significant benefits of this system is the low maintenance design with a Servo Motor, gearbox and linear bearing design for the oscillating motion. There are no hydraulics on the machine there is no need to rebuild the oscillation system periodically. If you would like to hook the system up to your data analytical gathering system, that is standard out of the crate.

The balls are delivered to the grind system by an elevator hopper. The continuous flow of balls fills a staging hopper which maintains the level in each ball delivery chute. A segregator separates the next group of balls and rapidly fills the multi-station grind zone. The regulating wheel movement is a 3-axis programmable movement controlled by on screen controls. This grind system is a perfect blend of rugged mechanical design with reliable tested servo motor motion control.

The system can be delivered with CE markings, as well as larger hoppers and conveyor feeders.

Ball Grinding System

OTHER NON-MEDICAL TG-12x8 SOLUTIONS

TG-12×8 Servo Cycle Infeed and Thrufeed Centerless Grinder

Well Rounded Centerless Grinder built for more robust applications

TG-12×8 Hi-Accuracy Centerless Grinding System

Centerless Grinding System for the Most Demanding Applications