Supporting Our Customers Is A Key Priority.

Bedrock is Done

Wednesday of this week serves as our first customer demonstration for our NEW bedrock series of centerless grinders. One of the first blogs that was written included a photo of the machine’s bed being machined at Rock of Ages in Vermont. Now the design has come to life and is a machine tool that is grinding applications to under .000010” roundness.

After our demonstration on Wednesday for a customer we will be starting to tool out the machine for IMTS. Outside of the machines new design, and superior accuracy we will have some other pretty cool accessories on it.

- New Magazine Feeder design that is easier to load parts into a hopper for longer unattended operation

- In corporation with Laser Linc we will have integrated into the machine a new LobexTM Lobing Detection System. It performs real-time analysis of centerless ground products to detect and report a constant diameter but out-of-round condition due to lobing of any frequency (e.g. 3, 5, 7, 9…).

- A full machine enclosure that gives full access to the machine from any angle

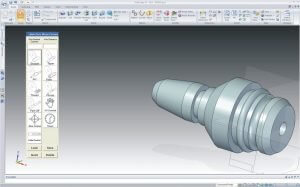

- New Software features for programming in virtual templates for CNC Dressing. This integrated system enables you to design your part or template on the machine’s interface. This tool also interfaces with your engineering software to bring the solid model on-board to your centerless grinder. From there it generates the Excel worksheet which will either dress your wheel or grind your part without ever seeing a G or M code.

We thought of everything, including a tool tray on an articulated arm that will keep your machine neat and clean, multiple language support, Internet connectivity for lights out grinding, and even a utility that can have the machine e-mail machine production statistics at a hourly frequency.

All of this adds up to pretty cool new machine.

Are Friday Afternoons Strange at Your Factory?

Today our granite machine bed was delivered for our centerpiece machine at IMTS. About 5 months ago we looked into the possibility of enhancing our machine as we started running into applications that required better tolerances. Two areas to address were thermal stability and vibration dampening. ( Hey every micron counts ). The granite machine bed was born.

Friday afternoons at Royal Master are funny, they either feature pure chaos as people call in last minute for parts or they are quiet, with the only calls from spouses looking for a choice between pizza or Chinese for dinner. There never seems to be anything in-between.

With the bed came a bunch of new ideas of the machine, many which without a doubt enhance the mechanical properties of the machine, but some are purely ascetic in nature. Meetings on the machine came at different times, nothing planned, usually a cup of coffee or Mountain Dew was in hand and it started out with a “What if we…. ” And ended with, lets get Todd to figure this out, it sounds good.

This bed has been highly anticipated here for the last 10 weeks as Rock of Ages in Vermont helped us develop a product that could be manufactured, but also meet our requirements. The result arrived today. When the truck arrived there was crowd, all eagerly anticipating the bedrock machined base, which arrived crated. But when uncrated, many just “Wow”

As many times as you look at a solidworks model, and visualize the end result, nothing prepared me for the relief to see the idea which started out as a “ what if” get uncrated. Looking at the certification paperwork that came with it, revealed another surprise. Just like a Born On date. Rock Of Ages who knew of our excitement to receive this, included a few photos of it in process. I have to say they got copied many times and passed around as everyone had to look at them, a lot.

After I finish writing this blog, I am out to the shop to go place a headstock, wheel guard and some other items which are finished on top of ...