Supporting Our Customers Is A Key Priority.

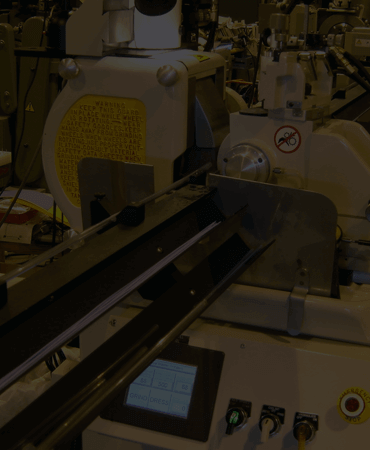

This is the Royal Master Wire Profile Laser Measurement Gauge. This laser gauge system has become an industry standard now for more than 20 years. The evolution of this gauge has introduced many improvements and yet the basic concept remains steadfast.

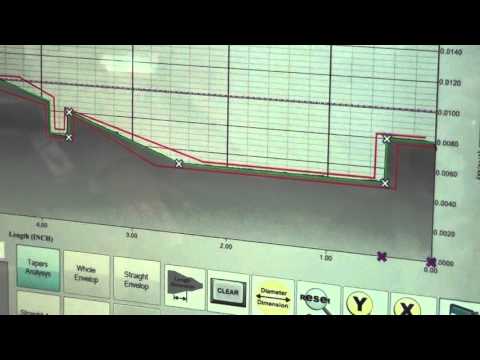

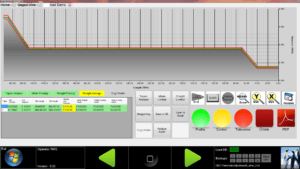

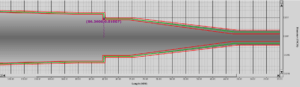

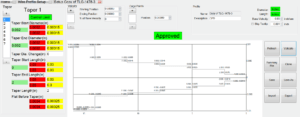

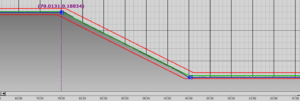

Pull a ground guide wire core through the 2 axis laser head using a linear motor. Create a near infinite series of data sets representing the coordinates of points along a line graph. This line graph shows the profile of the measured ground guide wire. Select the analysis type for presenting the data in the format you choose. Save, print and / or send the result. Reading the results is as easy as looking at a map on your phone with zoom in and out touch screen.

This Wire Profile Measurement Gauge can be networked to your office computer to retrieve and evaluate database information from a remote supervisor computer.

Specifications and

standard features

| The New Gauge System features Advanced Hardware including: |

|---|

| Granite Table for Thermal Stability, Rigidity and Flatness of Mounting Platform. |

| The structural steel frame is mounted on casters making the gauge transportable without requiring recalibration. |

| The current system uses the Laser Linc brand Laser Micrometer Head. |

| The linear data points are collected with a Parker High Speed 0.1 micron Linear Servo Motor Table and Gemini Servo Motor Drive for high accuracy length measurements. |

| Dual Touch Screen Monitors. |

| State of the art i7 powered industrial PC with additional dedicated graphics card |

| C# programming backbone for modern, user friendly operation |

| One sample every .0001″ inch when pulling at 0.125 inches per second |

| One sample every .001 when pulling at 1.125 inches per second |

| Multiple layers of Password Protected Screens |

| Standard Query Language (SQL) database. |

| Unlimited program storage |

| Custom password protection |

| Add an operator |

| New Gauge System Has Many User Friendly Features: |

|---|

| Touch optimized software with large, easy touch graphics and virtual pop-up keyboard for data entry. |

| One click diameter |

| Two click pitch |

| Two click diameter difference |

| Length and Diameter Zooming |

| One click gaged wire save |

| Simple drag and release zooming |

| Print / Save feature after analyze with added Print only button. |

| Automatically display .pdf wire print of active profile on second monitor |

| Profile part drawing linked to display with gauging. |

| Simple .pdf creation |

| Remotely view gaged wires |

| New Gauge System Has Enhanced Analysis Features: |

|---|

| Automatic Wire Analysis. No need for operator to pick intersections or “find” gauge points |

| Save analysis without printing. |

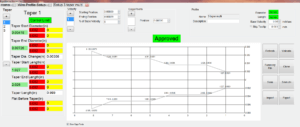

| Pass / Fail in Measurement Summary File. |

Choose analysis option for each recipe:

|

| Moveable Datum Point feature |

| Adjustment Limit Feature (yellow tolerance lines) |

| Pass, Pass Adjust and Fail Indication for operators using algorithms |

| Measurement Summary report with export to .csv capability. Final result is compatible with Excel or Minitab. |

| Integrated SPC – Process Capability, X-Bar, and Range Charts |

| Show gage points and flats in on-screen graph. |

| Ability to Zoom on Graph while analysis results are shown. |

| Simple access to Report of Analysis. Results organized by user chosen variables. |

Analysis Reports include:

|

| New Gauge System Has Many Advanced Recipe Creating Features: |

|---|

| Simplified Recipe Writing system or Wire Profile Creation using point to point data entry |

| Enhanced multiple settable linear velocities for more data-points in critical areas |

| Upload recipe and database files to any “disc like” storage device, i.e. USB Stick. |

| Recipe selected as Approved to Gauge (previous version of Recipe can be selected as Not Approved to Gauge) |

| Direct enter of fields in writing recipe versus scrolling. Do not need it in offsets. |

| Increase limits of maximum Paddle Length amount. |

| Increase limits of maximum Paddle Length tolerance. |

| Linking of your Profile to your Lots |

| Multiple Gauge Point Setting |

| Type in recipe values or up/down scroll. |

| Save to Excel |

| Save to Database |

Laser Gauging System

Other Wire Grinding Solutions

Catheter & Dialator Grinds

Billions of catheters ground since the 1960s

Needle Grinding System

1250 Trocar Needles Per Hour Production Rate Per Machine