Supporting Our Customers Is A Key Priority.

Our Truck is somewhere between RMG and Chicago

We loaded out on Saturday and everything went smoothly, no issues. We took up most of the flatbed trailer, with just a little to spare. We added Todd’s, Bob’s and Jesse’s bicycles as they like to ride up and down lakeshore drive in the morning before breakfast. They will have a blog during the show about that experience. They normally have good stories during breakfast about the morning ” sights”

Here are some photos from Saturday Morning:

So the plan for the rest of the week is the following:

Tuesday, fly to Chicago, Lay the flooring, get rough electrics pulled from the floor, chalk out the machine layout

Wednesday, take delivery of the machines, get the spotted, run electrics and air under the flooring

Thursday, Put booth up, hook machines up

Friday, Power up all machines, and put everything that was shipped away

Saturday, organize, and clean up the booth for Tuesday when Service engineers come to get all the machine running.

I’ll be posting update photos as we go along.

We ship on Saturday…

Even though IMTS is still technically 21 days away from the opening ceremony, we ship all of our equipment and support materials on Saturday. We have 16 different items packed on a 53′ flat bed and for full disclosure, this is the first time in 4 IMTS shows that I had to send an additional package to the advance warehouse. It has always been a source of personal pride that I fit a whole lot of stuff on the truck, and in past years, I have had no more than 6″ left at the back of the truck when we were all done packing it up. I had tried a multitude of combinations and at the end of the truck, there was still always one skid of stuff left over. Just not enough room.

This is a photo of last years truck:

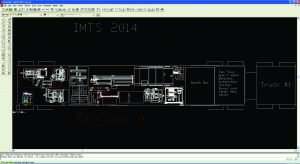

This year, as usual I have it in AutoCAD to make sure that everything could fit, and well, it did not.

Something that you’ll never see on another centerless grinder…

Royal Master has always been on the forefront of graphical machine controls, since we introduced the Generation 4 Guide wire grinding machine back in the Early 1990’s with a windows machine control We were one of the first machine tools to offer such a package to the world. Since then we have been offering new more innovative and user friendly systems. We were the first to offer a light out system that was intelligent enough to be viewed from the couch in your living room Then we offered a machine control that e-mailed you statistics, such as up time, parts per minute, and maintenance alerts.

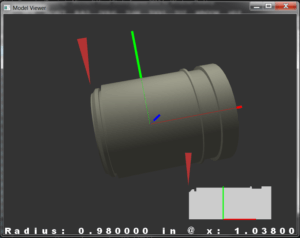

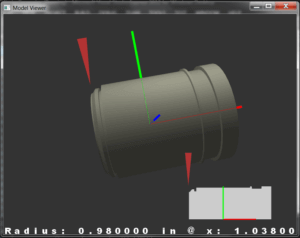

For IMTS 2014 we are bringing a custom designed 3D Graphical package for CNC dressing simulation. Before you ever put a diamond or diamond disk to the wheel, simulate the dress right from your Excel sheet, or watch the progress of your dress on the screen as the dressing is occurring. Rotate 360 degrees on any axis to see the shape, or watch the coupon in the lower right hand corner for a more traditional look at the dressing progress.

This graphical package is standard equipment on all machines with CNC dressing programs.

What happened last night at Royal Master Grinders..

To be fair to Ryan, we knew that he is a good sport, so when we needed someone to jump into the TG-12×4 bedrock enclosure to wire up the limit switches, we nominated him. Being a good sport, and the fact he wasn’t looking, this is what happened. We let him out after we all ordered outback, but before we ate. Just for the record, He had a Ribeye for dinner last night.

TG-12×8 #1 Sold!

Royal Master Grinders would like to thank our launch customer for placing the first order for a TG-12×8 TF machine. They will be Thrufeed grinding ceramic with a metal bond diamond wheel. The wide wheel, 12″ in diameter with the outboard bearing was an attractive element of this system, as well as the 8″ diameter regulating wheel.

The entire Royal Master family wants to thank them for this order!