Supporting Our Customers Is A Key Priority.

Introducing the TG-12×8 Centerless Grinder, and BTW, IMTS Ships in a little more than 3 weeks

August 1, 2014 has arrived and Royal Master has been awaiting this day for a while now. All 50 employees of Royal Master Grinders are proud to introduce the Model TG-12×8 Centerless Grinder. This machine has all of the accuracy as our TG-12×4 series, but with twice the wheel width.

When Royal Master Grinders set-out on this project, we were adamant that we would not be re-branding the current models with Fancy names or stretching existing designs. We wanted to manufacture the most robust system possible, conceived from the spindles outward. If your looking for a summary at a quick glance, this pretty much sums up this system:

• 12” diameter Grinding Wheel 8” wide, 8” Diameter Regulating Wheel, 8” wide

• Applications up to 3” Diameter

• Micron Tolerances

• Conventional Sizing system, Thrufeed Microsize Adjustment, Air Over Hydraulic Plunge system, Servo Operated infeed, Hi-Accuracy CNC

• Machine weight 4000 lbs

• Twin Grip Ridged Spindle Designs

• Bedrock Platform of 8” thick granite as standard equipment

• Servo Driven Regulating Wheel drive as standard equipment,

• Easy to use Ram bed swivel design and work rest holder advancement system.

• Permentely mounted dressers, stepper motor and ball screw cross drives

• Dressing systems available:

o Air Sensing Dressers ( Standard Equipment )

o Automatic Dressers for both Grinding and Regulating wheel

o Over the wheel CNC Dressing for both Grinding and Regulating wheel

o Rotary Diamond disk CNC grinding wheel Dressing

• Ram Bed Swivel design that incorporates Turcite antifriction material for smooth friction free diameter adjustments

• Cam Out capability at an affordable cost.

• Automation from operator assist devices to fully robotic systems

At IMTS we will be grinding on two separate systems, a Thrufeed microsize system, and a Hi-Accuracy system. Both will be displaying demanding applications, thrufeed grinding titanium bars, and infeed grinding an industrial gearbox part. Both system will have loading options on them. The Thrufeed machine will have a outboard bar stock support. The Hi-Accuracy machine will have a pick and place loading system with outboard conveyors.

We have more in our 40’ x 40’ booth at IMTS, we have four other machines. We will also have our TG-12×4 BEDROCK centerless grinding system with a new enclosure system. this new enclosure is very streamlined and will meet many of the stringent health and safety standards that companies have in place. This machine will be grinding a fluid dispensing valve, robotically loading and unloading. After unloading from the grinder, we will be gauging, and re-palletizing the parts. We are very excited about showing this machine off, especially the new enclosure.

I have below some photos of us preparing for the show so far!

The first part that was made for the TG-12×8 Machine! The main spindle….

The day the Base Arrived at Royal Master for the TG-12×8

A quick assembly when the Ram Bed was finished ground

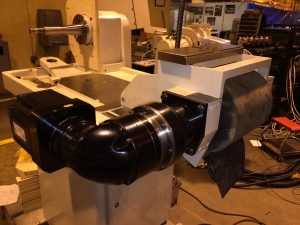

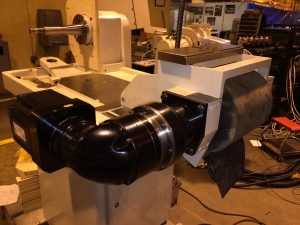

Regulating wheel spindles ready to go out and get wheels molded to them

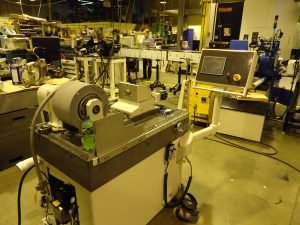

Regulating wheel mounted in the housing with Servo Drive and gearbox

John Memmelaar Sr reviewing the Hi-Accuracy Machine’s Ram bed with one of our Engineers

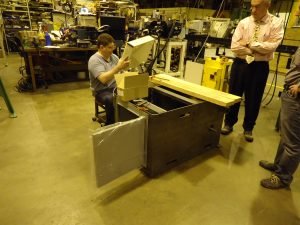

Thrufeed Machine Getting ready for photos

Our TG-12×4 Bedrock Enclosure Arrives!

Teamwork Bringing it in!

Stop Back to see More updates for the Show and more about the TG-12×8 machine