Supporting Our Customers Is A Key Priority.

Simply put, the TG-12x8 was designed from the ground up to be the most accurate and versatile system available from the .002” to 3.0” diameter grinding range. Grind one really big part or multiple parts at one time, The TG-12x8 will hold sub micron tolerances all day long.

The TG-12x8 Hi-Accuracy machine has become an extremely integral part of the 12x8 family over the last 4 years. With many systems sold around the world, we are grinding everything from high end aerospace applications, high volume automotive and heavy equipment parts. One particular project for Asia was a transmission valve grinding company that is grinding multiple valves at one time On the opposite end of the spectrum we are grinding medical guidewires down to .002” diameter (.05mm).

Built on a Starrett surface plate granite platform, the accuracy starts with flatness of the granite to less ness than .0002” flatness over the entire surface. The spindle design is built for accuracy and rigidity with a collaborate effort with Timken Bearings engineers to design a main spindle and outboard bearing to deliver the most accurate design. This system has almost zero deflection under the heaviest spindle loads.

On the regulating wheel side, the straddle bearing system and the 8” diameter 8” wide Regulating wheel offer quick regulating wheel changes as well as a large regulating wheel for less dressing frequency. The Timken bearings give a ridgid system while the air purge keeps grit and fines from contaminating the bearings. All TG-12x8 Systems have a servo driven regulating wheel. For Cam Out systems we program the regulating wheel to stop while loading the part into the wheels.

The ram bed design takes full advantage of the .1 micron glass scale with Schneeberger anti friction cross rollerways enabling size compensations of .000010” accurately. Other grinder discuss their hi-accuracy machines grinding to under a .0001”, we grind to better than half of that. We have had gauge pin results to less than .5 micron round and straight.

There is a multitude of dressing options both the grinding and regulating wheel on this system, they are the following:

- Over the wheel air sensing dresser with standard stepping motor cross travel

- Over the wheel air sensing dresser with automatic dressing functionality off a template

- Over the wheel CNC Dressing

- Horizontal CNC dressing for the grinding wheel for Rotary Diamond disk as well as single point

- Diamond Roll Form

Why a High Accuracy System rather than a Servo Cycle?

Our recommendation for the Hi-Accuracy is based on the grinding extreme close tolerance grinding of multiple diameters and transitions. Our next question is if post process gauging with feedback to the system making it closed loop is a consideration, as well as a high degree of automation including robotics. If you answer is yes to any or all of the above we recommend this system.

All of our TG-12x8 series machines use granite as a thermally stable and ridged platform which translates into he most accurate system in the price range. For the basic Hi-Accuracy system, it is a basic two axis system. It has our .1micron glass scale and accurate ram movements 2.5x the scale resolution regardless of options, all or all Hi-Acc machines make accurate ram movements in .000010” incrementations. The ram bed position control is our high accuracy frictionless cross roller way with ball screw and servo motor movement. The HMI is 17 inch touch screen with all machine function controls. The Windows base programming is remote accessible for data report sending and diagnostic connectivity.

All Hi-Accuracy systems have the ability to take advantage of the Advanced Machine Optimization (A.M.O.) cloud database. By activating the AMO feature on your Royal Master your grinder will start to report machine specific information to our secure cloud database. Receive up to date reports of how your machine is performing and have the app remind you of your PM based on time of use. Check error logs, part counts, cycle times, part numbers and more. With AMO, you can stay connected to your grinding process and receive up to date information to optimize your manufacturing process.

We have partnered with companies such as Greymills coolant filtration, Losma Air Filtration, Cognex, Universal Robots, Fanuc, Keyence, SBS Dynamic Wheel Balancer with Acoustic Emission Gap Elimination and Analysis Tool. All of our partners have been an integral part of making custom systems for a variety of applications presented to us.

The extensive engineering that went into this system is evident in the outstanding results of the customer’s applications. We discuss applications with sub micron tolerances, challenging part geometries and automation that includes Robotic loading and unloading. It is these applications why the TG-12x8 is the machine of choice.

Specifications and

standard features

| Specifications | |

|---|---|

| Machine Capacity | .002” to 3.0” (.05mm to 76mm) |

| Accuracy | .00004” (.001mm) |

| Sizing Increments | .00001” (.25 Micron) |

| Grinding Wheel | 12” diameter x 8” wide (304mm x 200mm) |

| Regulating Wheel | 8” diameter x 8” wide (200mm x 200mm) Servo Driven 0-500 rpm |

| Spindle Power | 10hp (optional 15hp) Spindle inverters available |

| Weight | 3800 lbs |

| Enclosure Options | Multiple options available depending on customer requirements |

| Dressers | Air Sensing, Permanently Mounted, stepping motor traversed with touch screen controls. (Programmable Dual dressing zones standard) Optional Automatic Dressing using templates |

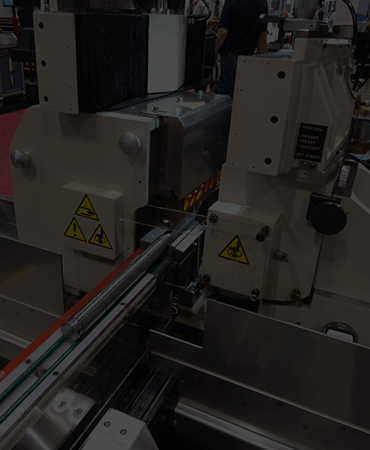

THE TG-12x8 HI-ACCURACY IN ACTION

OTHER NON-MEDICAL TG-12x8 SOLUTIONS

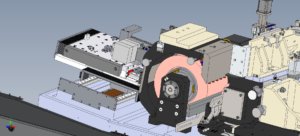

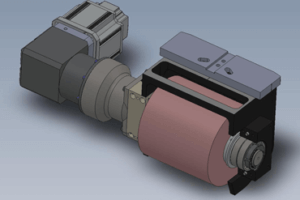

Ball Grinding System

Grind up to six 1.4” balls in less than 10 seconds

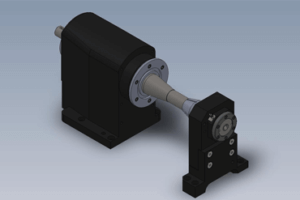

TG-12×8 Servo Cycle Infeed and Thrufeed Centerless Grinder

Well Rounded Centerless Grinder built for more robust applications