Supporting Our Customers Is A Key Priority.

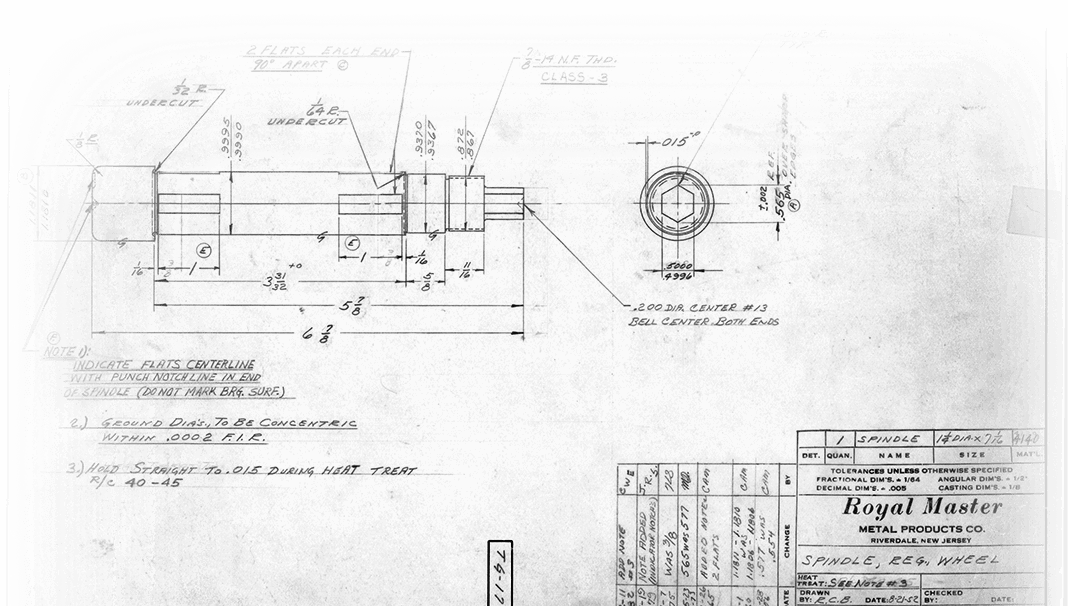

Our first design of a centerless grinder came in the days of a slide rule, mechanical pencils and thousands of drafting teachers around the world preaching the phrase “Line weight and Line control” to students worldwide. Since the early 1950’s when we had flat file cabinets full of papers and drawings, we now have cloud storage and a server to hold the terabytes of solid works drawings that we have designed over the years. We are certainly looking forward to the next renaissance of design technology!

We are highly proud of our engineering of our machines, our feeders and our control architecture. It is a three prong approach to the design of our machines as all of the three areas need to be in concert with each other. This makes for a solid system and one that you will enjoy for years to come. We use engineering aids such as Finite Element Analysis to evaluate our designs, 3D printing to try out concepts and a peer roundtable system of design review.

We are happy to work with our customers on specialty designs. We have many customers who come to us and simply say "I have this idea for a feeding system“ or can you make me this accessory for me, it will make my operators job easier. We have worked on many projects over the years on our TG-12x3 and TG-12x4 series, and now on our TG-12x4. One type of machine doesn’t necessarily fit everyone’s budget or application. For example, we made a few TG-6x3 table top machines over the years, a machine to grind golf balls, and a Rotor grinding for motor rotors. Our specialty equipment doesn’t end and wont stop there.

Our engineering staff takes great pride in their support of their equipment. We use the latest technology to interact with customers remotely for both mechanical and electrical inquiries. For program modifications, we can easily log into your machine and troubleshoot or make program updates.

Please take the time to review the engineering of our machines by following the link below. You can discover the different models of machines as well as their components for a greater understanding of the equipment.

Want More ?

OTHER TG-12x4 SOLUTIONS

TG-12×4 Infeed / Thrufeed Servo Cycle

Programmable Infeed / Thrufeed Grinding Ideal for a Job Shop Environment