Supporting Our Customers Is A Key Priority.

Since we began producing centerless grinding systems in 1950, we have made many thousands of grinding machines. Some were specialty products made for one specific task, while others were based on technology that evolved over the years. Royal Master makes it a point to be able to support every one of our older products.

We have enough stock of electrical components and mechanical parts to support even serial number #112 that is still running today. If you need a part for your Generation 4 guidewire grinder or a Autocycle machine, we can make it for you even if it is not in stock. The bottom line is - we support our customers so when they purchase a machine they have the peace of mind that we will stand behind them despite the age of the equipment.

We also offer rebuilding services for your in-house equipment or may have bought from a dealer or even Ebay. If you buy something, give us a call and we'll be happy to visit you to review the machine and give you an a la carte menu of what could be done. We can help you as much as you would like with this process. We also offer functional and full rebuilding services.

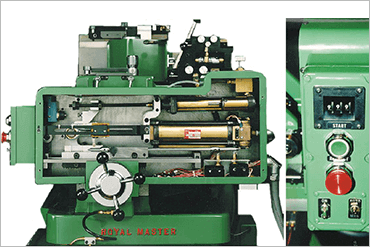

Some common upgrades available are servo cycle retrofits to replace automatic cycling infeed units, servo regulating wheel drives, grinding wheel inverter upgrades, and many other popular upgrades.

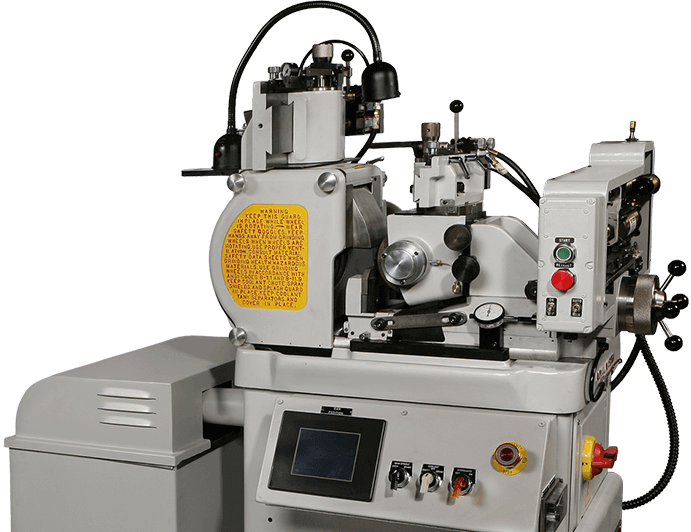

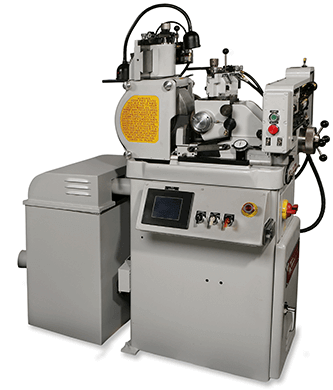

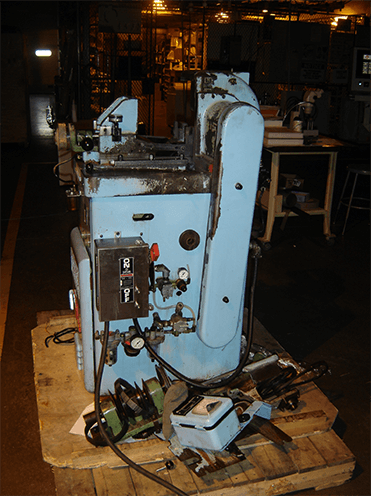

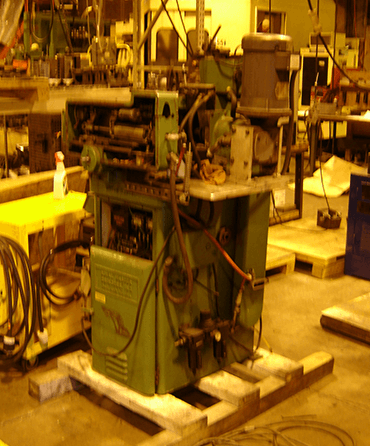

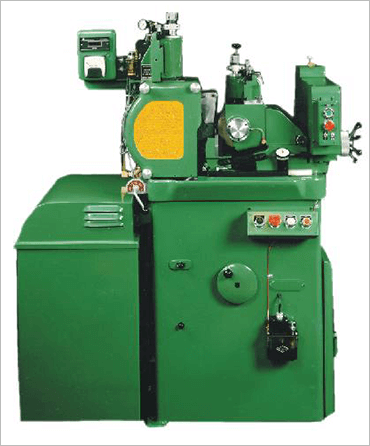

TG 12x4 AUTOCYCLE MACHINE

Over the last 50 years Royal Master has produced thousands of automatic cycling machines. These machines are still a viable workhorse of many companies. With components still readily available from Royal Master, companies have the ability to keep using machines that are very much still serviceable. With all components available as new, rebuilt, or as part of a rebuild kit, customers have confidence that Royal Master will be able to maintain and service their machines for years to come. For example, Cycle Blocks, main spindle, and regulating wheel housing rebuilds are available with a 24-hour turnaround.

Other components such as allspeed drive units are also still available but over the years customers have asked for options to replace this unit. About 10 years ago Royal Master switched over our new machines from the belt drive system with transmission case and universal joint to a direct coupled servo Driven regulating wheel system. This system is available to retrofit to any age grinder and offers a large component cost savings when looking at the replacement of the allspeed drive, transmission case and universal joints. The ultimate result is a more maintenance free system.

Please email (mailbox@royalmaster.com) or call us at 201-337-8500 for more information about servicing or upgrading your TG-12x4 Autocycle machine.

Rebuilding Program

Many of our machines over the years have been sent back to us after many years for rebuilding, Functional or complete, the customer has many options. One notable case study is a German customer sent back his machine after it registered over 23 million cycles on an automatic cycling unit. Feeling its life was just beginning, we rebuilt it and put it back in service for another 23 million.

Other components such as allspeed drive units are also still available but over the years customers have asked for options We accept all machines in all conditions for rebuilding. We will work with the customer on a budget and work to stay within that budget. No matter the extent of the rebuild, our goal is to make sure it still grinds under 1 micron straight and round upon machine checkout.

Have a rebuild need? Email or call us at 201-337-8500 for help.