Supporting Our Customers Is A Key Priority.

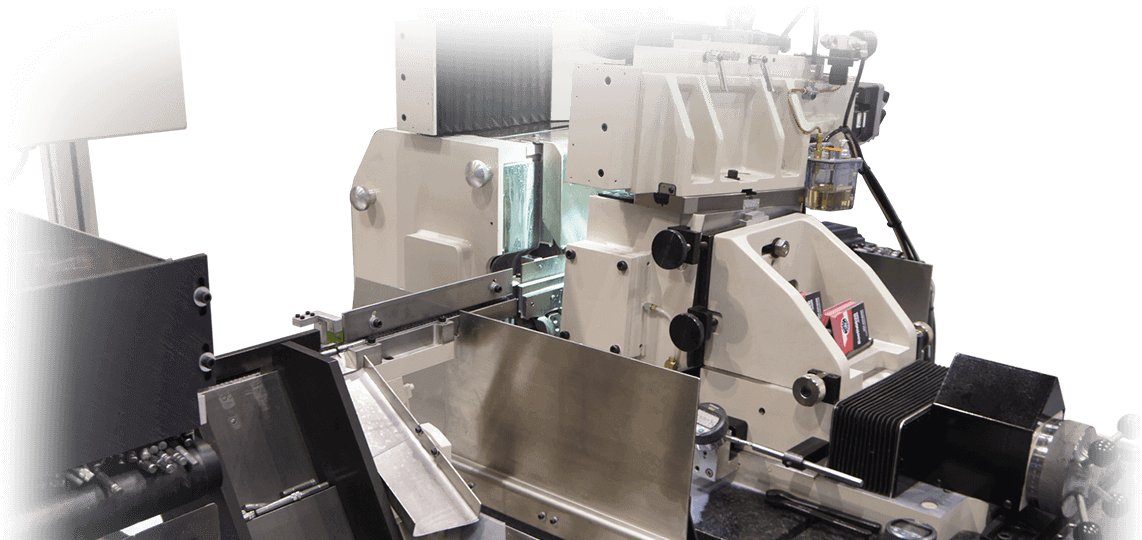

Introduced in 2014 the TG-12x8 was an instant success. With its 8” (200mm wide) grinding wheel, and its granite machine bed, it is not matched by any other manufacturer. With all the standard features to be able to grind under a micron straight and round, the TG-12x8 has no competition.

The TG-12x8 offers a grinding wheel diameter of 12” (300mm), a regulating wheel of 8” (203mm) diameter, both being 8” (203mm) wide. The advantage is clear, wider wheels allow for heavier stock removal for thrufeed grinding,

The grinding wheel spindle design has 4” (100mm) diameter bearings, with three sets of class 7 ABEC angular contact Timken bearings. It is inside a larger headstock with an outboard bearing for a twin grip design. This design gives the grinding wheel superior accuracy. The regulating wheel with its 2.25” (57mm) spindle and Timken bearings allows for the most demanding applications to be ground with zero deflection of other machines with smaller spindle designs.

Growing outward from the spindle designs, the vision of the machine became clearer, it had to be placed on our Bedrock platform. The machine sits on our 8” (203mm) thick Starrett surface plate quality granite. The .0002” (5 micron) flatness specification forms a perfect platform for such a robust spindle design. The granite known for its rigidity and thermal properties provides a superior platform to other machines on the market that have thinner cast iron beds, and makes it as strong as those who have machine platforms twice the physical size of the TG-12x8.

Standard on our TG-12x8 is servo driven regulating wheel spindle with 170 foot pounds of continuous torque, and a 10:1 gearbox. We also added stepper drives for programmable traverse rates and ball screws to our dressers as standard equipment.

Ram bed positioning has also been upgraded with a longer and wider ram bed. The upper ram, utilizes hard chrome and Turcite for the most efficient and accurate movements. This friction free ram system coupled with options as the thrufeed microsize adjustment and the servo cycle systems allows for precise micron movements at a lower cost.

Applications such as titanium bar stock, PCD diamond tools, and hard carbides are pedestrian for this machine, other companies boast these applications. The TG-12x8 looks for larger diameter applications up to 3” in diameter that will put all this rigidity and engineering to good use.

Specifications and

standard features

| Specifications | |

|---|---|

| Machine Capacity | .002” to 3.0” (.05mm to 76mm) |

| Accuracy | .00004” (.001mm) |

| Sizing Increments | .0001” on dial Indicator, .000040” on digital indicator |

| Grinding Wheel | 12” diameter x 8” wide (304mm x 200mm) |

| Regulating Wheel | 8” diameter x 8” wide (200mm x 200mm) Servo Driven 0-500 rpm |

| Spindle Power | 10hp (optional 15hp) Spindle inverters available |

| Weight | 3800 lbs |

| Enclosure Options | Multiple options available depending on customer requirements |

| Dressers | Air Sensing, Permanently Mounted, stepping motor traversed with touch screen controls. (Programmable Dual dressing zones standard) Optional Automatic Dressing using templates |

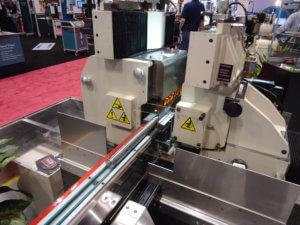

THE TG-12x8 THRUFEED IN ACTION

OTHER NON-MEDICAL TG-12x8 SOLUTIONS

Ball Grinding System

Grind up to six 1.4” balls in less than 10 seconds

TG-12×8 Servo Cycle Infeed and Thrufeed Centerless Grinder

Well Rounded Centerless Grinder built for more robust applications