Supporting Our Customers Is A Key Priority.

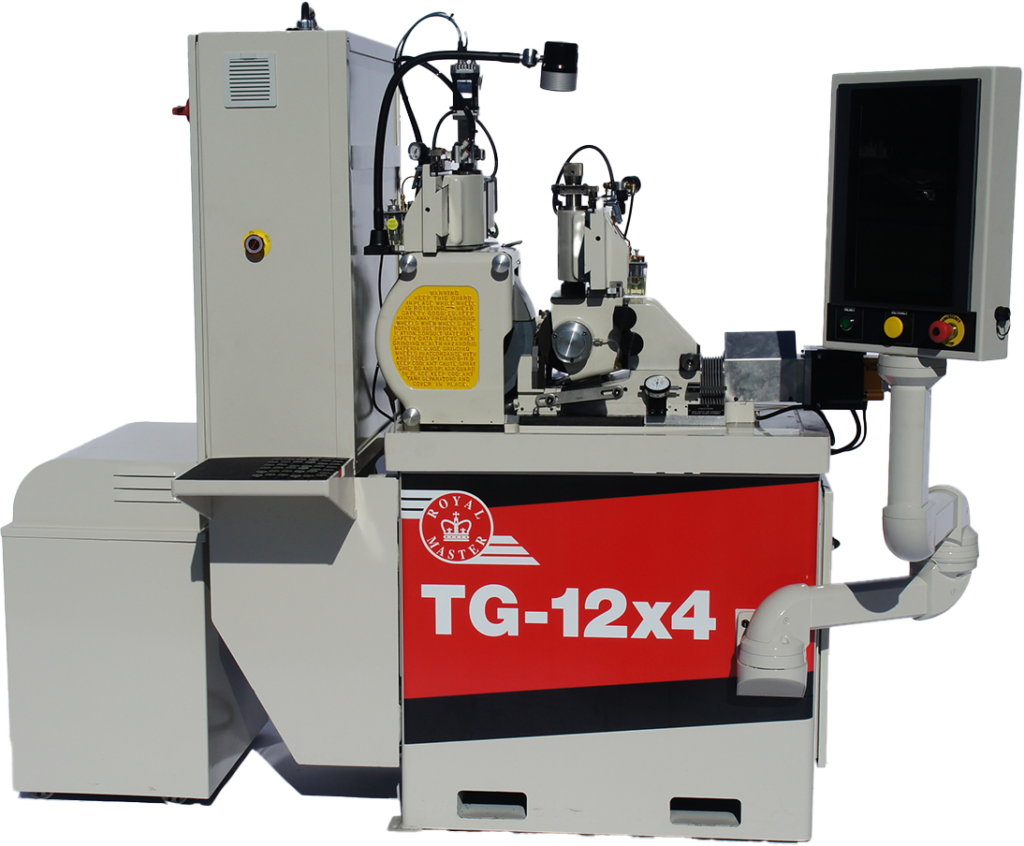

Since 1950 when our first centerless grinder was introduced, our TG-12x4 series has been a staple of thousands of companies around the world. Its compact size coupled with its superior accuracy to any other centerless in this size range makes it an ideal fit for many applications. The TG-12x4’s new cleaner look is noticeable, all while boasting many newer features in the last few years. This machine, over its 67-year production run, has seen thousands of different applications that the world offers.

The TG-12x4, a staple of machine shops, has evolved from holding “space age tolerances” of the 1960’s to a micron, tolerances that are required today. The machine’s technology has improved over the decades with upgrades to spindles, regulating wheel housings, and dressers, as well as electrical upgrades to conform not only to US standards but CE and UL standards as well.

The TG-12x4 has the ability off the assembly line to grind under a micron (under .000040”) straight and round. That’s the quality that’s expected of every machine. Sometimes holding .0001” (2.5 micron) just isn’t good enough.

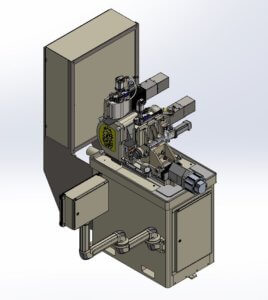

The TG-12x4 servo cycle machine couples standard dovetail and gib ram bed technology with a Servo Motor and Ball Screw movement. The controls system is Parker Automation with motor resolution of .015 Microns. The new machine control has an intuitive color touch screen. Added screen functions include automatic size compensation, automatic wheel dress with compensation, wheel dress parameters, infeed grind parameters saved on power down and infeed grind parameters library storage feature.

Keeping with our clean machine design we have eliminated the hydraulics from the machine and both wheel dressers now feature motor cross feed and motor down feed. This makes automatic wheel dress possible. The new Servo Cycle when equipped with this auto dress feature has the ability to auto dress and to do auto compensation. This auto dress feature uses templates for tracing the profile.

The optional Regulating Wheel Lateral Adjust feature allows for fast alignment of the Regulating Wheel Form to the Work Wheel Form.

The Servo Cycle System is:

- Designed with a Ball Screw and Frameless Servo Motor with Rotary Encoder

- Optional Linear Glass Scale

- Infeed and Thrufeed Grind Capability

- Easy-to-Use Touch Screen Operator Interface

- Programmable Infeed Cycles can be saved and recalled with unique file names

- Thrufeed Grind with fine resolution positioning to 0.000,010” of an inch or 1/4 micron increments

- 2” of Ram Bed travel allowing for removal of Grinding Wheel

- Digital Read-out of Ram Position

- Tachometer and Ammeter Display on screen

- Library Storage on PLC of multiple Infeed Cycle Parameters

- Expandable I/O for Automation

- Servo Motor Driven Regulating Wheel

- Available communication for Feed Systems

Specifications and

standard features

| Specifications | |

|---|---|

| Machine Capacity | .002” to 1.5” (.05mm to 38mm) |

| Accuracy | .00004” (.001mm) |

| Grinding Wheel | 12” diameter x 4” wide (304mm x 100mm) |

| Regulating Wheel | 6” diameter x 4” wide (152mm x 100mm) Servo Driven 0-500 rpm |

| Spindle Power | 7.5hp (optional 10hp) Spindle inverters available |

| Weight | 2500 lbs |

| Dressers | Air Sensing, Permanently Mounted, stepping motor traversed with touch screen controls (programmable Dual dressing zones standard) |

THE TG-12x4 SERVO CYCLE

OTHER NON-MEDICAL TG-12x4 SOLUTIONS

TG-12×4 Basic Thrufeed

Micron Accuracy for Thrufeed Grinding