Supporting Our Customers Is A Key Priority.

Dental

Royal Master’s involvement in the Dental industry began many years ago with the centerless grinding of conventional dental burrs. These burrs had many different geometries and came in either Stainless Steel or Carbide varieties. Many companies over the years used TG-12x4 machines with automatic cycling units, and with the addition of magazine part loaders making it an unattended operation.

Over the last 10 years there was significant advancement in material technologies in relation to the Dental industry. Exotic composites and the NiTi files and probes have become a staple of many companies’ product lines. Royal Master has partnered with many companies over this time to deliver game changing products.

We were introduced to Fiber Posts about 10 years ago, and we developed a number of systems for this application. We delivered to the first company in the world to make these a TG-12x4 thrufeed machine, a TG-12x4 autocycle machine, and a GX with an auto loader. The TG and the GX machines were both equipped to run lights out. Over the last 10 years, we have sold over 25 machines worldwide to make these products.

Endodontic files were introduced to us after the well-known patent expired. Being able to shatter previous cycle times of homemade machines and more expensive options, Royal Master gave dental manufacturers worldwide another option. The point that makes our GX3 machine so unique then other systems in the world is the ability to grind the parts from a spool of raw material. No need for cut to length blanks or time-consuming taper grinding. the GX3 machine does a complete part in less then 55 seconds.

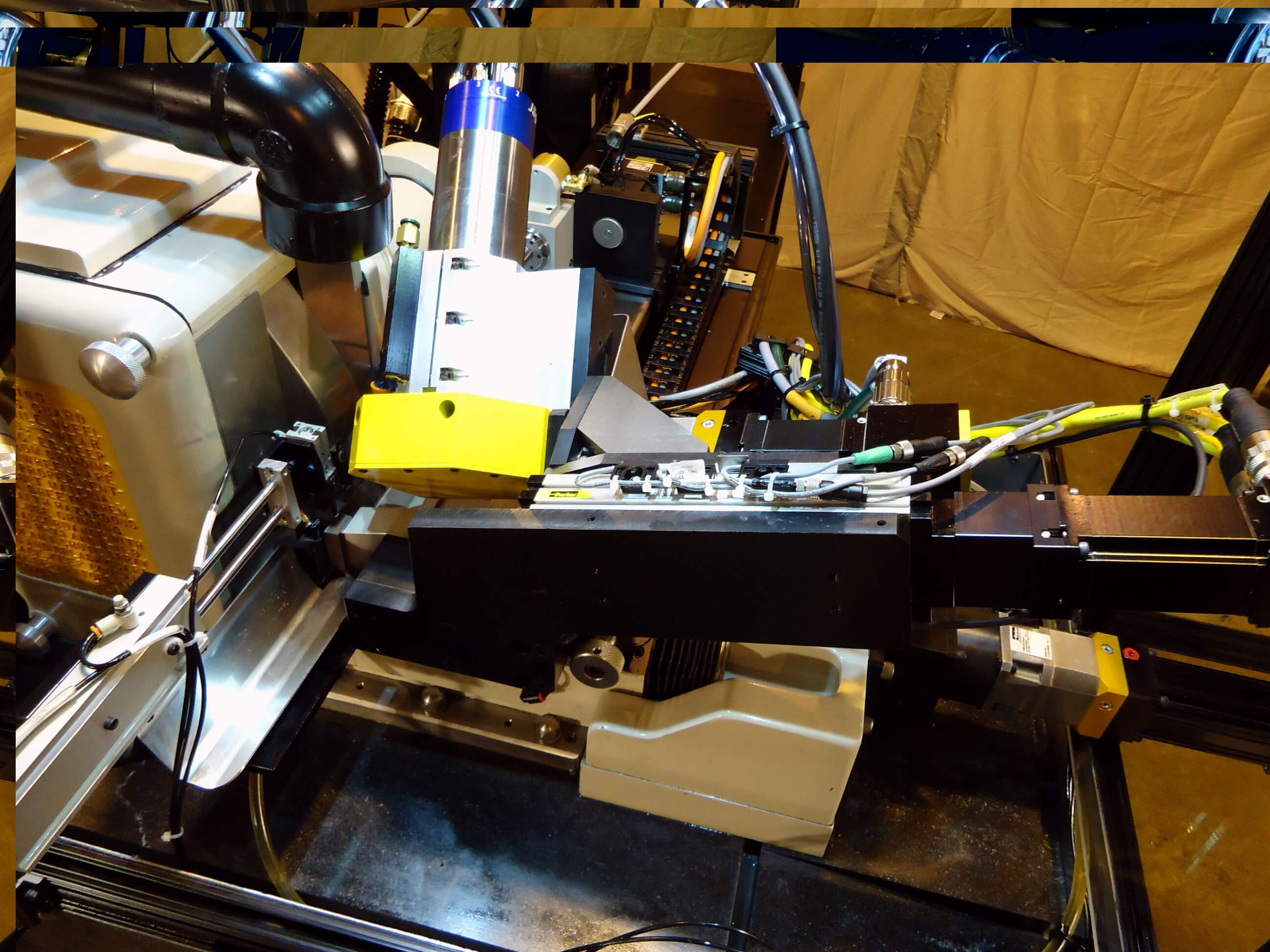

ENDODONTIC FILE GRINDING

The new Royal Master Generation X3 puts an end to the multi-operation process of producing complex part profiles. No more separate process for each part profile feature. No more cut to length and deburr. No more pre-pointing. No more taper grind. No more fluting. No more grinding calibration lines. No more grinding flats. No more grinding chamfer on back end.

FIBER POSTS

The grinding of Fiber posts is a simple process. The TG-12x4 process uses cut to length parts, and the GX uses long rods, usually 1-2 m long. Both will run fully lights out without any operator intervention.