Supporting Our Customers Is A Key Priority.

APPLICATION

INFEED GRINDING SEGMENTS ON A NITI TUBE

CHALLENGE

Multiple part diameters, lengths, auto gauging and machine feedback as well as lights out.

Solution Delivered

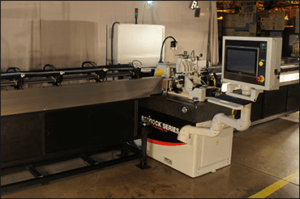

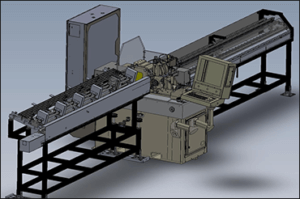

The system developed for this application was tailored specifically for their requirements. Working in conjunction with the customer and a vision system integrator, we developed a system for the customer to meet their needs. We began with our TG-12x4 Hi-Accuracy machine with CNC dressing on the grinding wheel. Built on the Bedrock Platform, the 8” thick Starrett surface plate provided an ideal platform for the quality required of this application.

The customer needed an automatic loading system that had the ability to feed 1mm up to 25mm diameter NiTi tubes of lengths from .5m to 3m long. Using a magazine feeding system and keeping CE regulations in mind, we designed and built a system using a programmable feeder to introduce the part into the machine for thrufeed grinding as well as indexing the part for segment grinding of various pitches.

The grind being done with a super abrasive grinding wheel, or in cases of R&D work a conventional stone wheel, allowed them to experiment with new forms in the grinding wheel, but for production they were able to switch to the superabrasive wheel provided by Dr. Kaiser in Germany for full unattended operation.

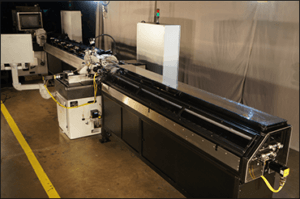

After the grinding, the part was expressed through a preliminary air wipe, and then transferred to a cleaning station. In this dedicated station, the part was wiped clean with high pressure air nozzles.

After cleaning it was lowered into the gauging station where a Keyence camera system gauged each of the segments to ensure that there was a proper transition

on each side of the segment. After moving down the entire length of the tube at programmable distances, the part was transferred to a collection station.

Machine Details

- TG-12x4 HiAccuracy Centerless Grinder

- Grinding Wheel 12” x 4” ( 300mm x 100mm )

- Superabrasive Grinding Wheel as well as conventional stone grinding wheel capability

- CNC Grinding Wheel Dressing

- Bedrock Series ( Starrett Surface Plate Platform )

- .025 Micron Diameter Compensation Capability

- HMI programmed in Multiple Languages Spanish, German and English for three shift operation

- AMO useage for Machine data tracking

Automatic Feeding System

- Capability of Multiple Part Diameters and Length Combinations

- Infeed and Thrufeed Capability

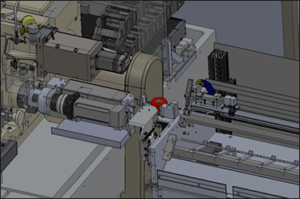

- For Infeed Grinding, a servo driven ballscrew and back-stop to index part through the grinding machine for repeatable segment grinds

- Exit Side Unloader cleans, and gauges the part in a infeed or thrufeed mode.

- Programmable gauging stations for inspecting the segments individually

- Feedback to HMI for automatic diameter control