Supporting Our Customers Is A Key Priority.

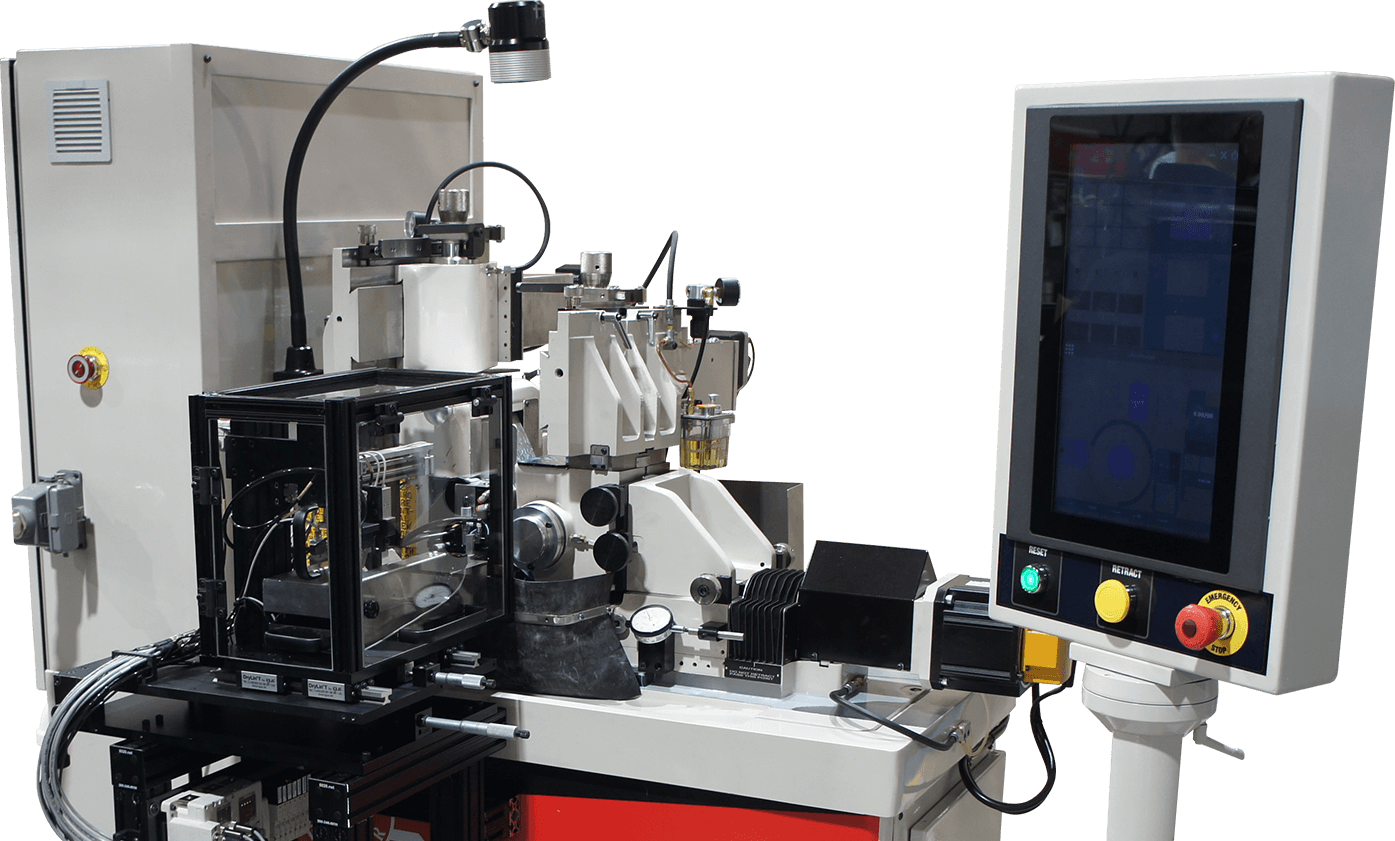

The TG-12x4 or TG-12x8 Servo cycle machines are the next step up in the evolution of guidewire discussions.

Where the decision comes to upgrade to this type of machine is when you:

- Have tapers greater than 4” long

- Want to do up to 5 tapers

- Are looking for a machine that can do a lot of different types of parts, not just wires. Applications include TF NiTi tubing, catheters, dilator tips, platinum electrodes, etc… All can be done on the same machine.

Material is not a concern for this type of equipment, Grind Stainless Steel, NiTi, plastics or any exotic metal without difficulty.

Specifications and

standard features

| This method of grinding is utilized when the taper length is less than the wheel width. In the case of the TG-12x4 it is 4” (100mm). For the TG-12x8 it is 8” (200mm) wide. It is a very simple method of grinding, and when using the right method of loading. |

|---|

| Designed with a Ball Screw Servo Motor for accurate ram motion |

| Optional Linear Glass Scale |

| Infeed and Thrufeed Grind |

| 0.0001" (2.5 Micron) Repeatability |

| Easy To Use Touch Screen Operator Interface |

| Programmable Infeed Cycles can be saved and recalled with unique file names |

| Thrufeed Grind with fine resolution positioning to 0.000,01" (0.00025mm) increments |

| 2" of Ram Bed travel allowing for removal of Grinding Wheel |

| Digital Read-out of Ram Position |

| Library Storage on PLC of multiple Infeed Cycle Parameters |

| Servo Motor Driven Regulating Wheel |

| The Gen 2 grinder provides you with end of wire sensors for: |

|---|

| Fast and Efficient Proximal End Grinds |

| Up to 5 taper wires, 17' long (5m) |

| Capable of Long and Multiple Distal Taper Grinds |

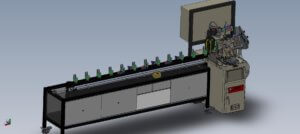

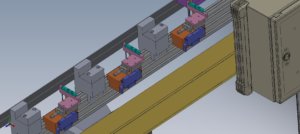

| Available with an Outboard Rail with Fiber Optic Eyes |

| Add an Auto Load/Unload |

| Available with a Finger Blade and Finger Regulating Wheel |

| Utilize 1.5" through up to 4" wide wheel and tooling |

| Automatic Blade Sizing |

| Tapers Screen to define profile parameters |

| Part Library for storing part profiles |

| Up to 30,000 wires per insert blade |

Simple Efficient Guidewire Grinding

Other Wire Grinding Solutions

TG-12×4 and TG-12×8 Servo Cycle Grinding Systems

The most versatile machine for up to 5 taper wire grinding

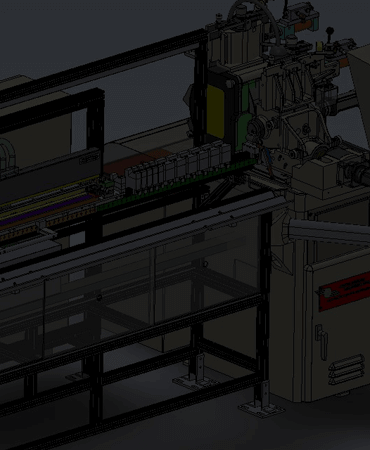

Automation of Guidewire Grinding

Operator Assist Devices to Fully Robotic Multitasking Solutions

Generation 5.8 Production Guidewire Grinding System

The machine that revolutionized the wire grinding industry is still producing millions of wires per year worldwide