Supporting Our Customers Is A Key Priority.

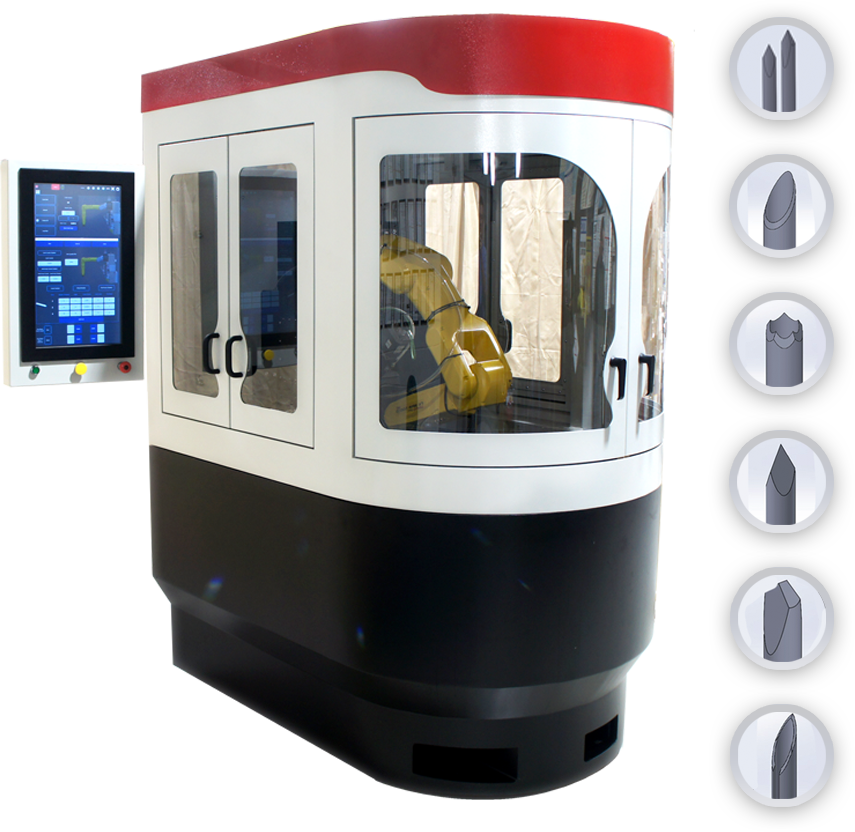

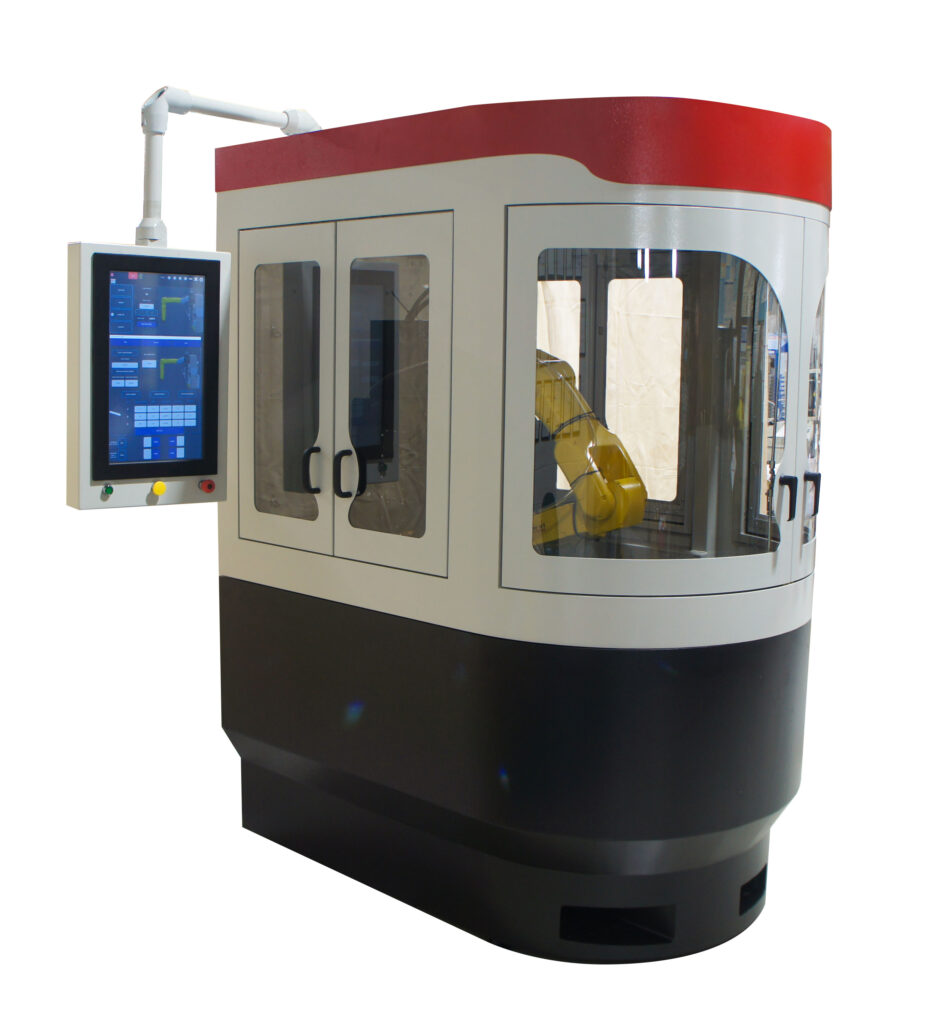

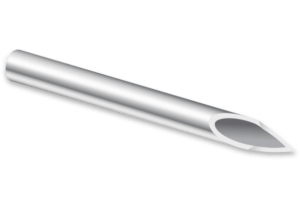

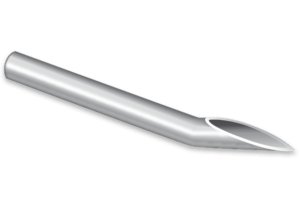

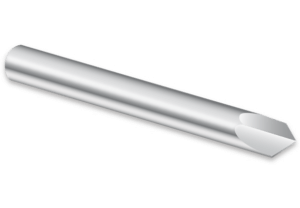

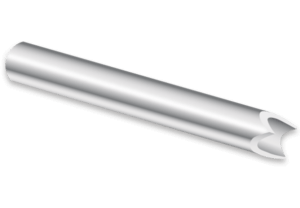

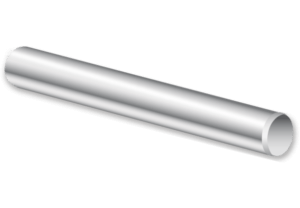

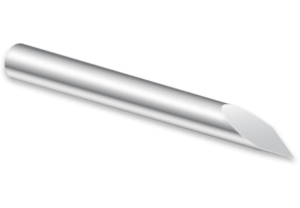

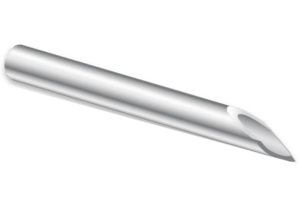

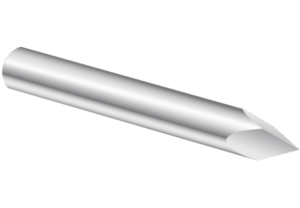

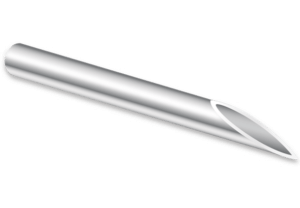

The Needle Grinder machine is a highly efficient solution for grinding various types of needles, including trocar, diamond tip, K-Wires, Franseen, and Menghini.

With options for manual, semi-automatic, or fully automatic loading methods, as well as automatic gauging after grinding, the Needle Grinder offers versatility and ease of use. Its user-friendly operator interface allows for quick programming and profile changes with just a few clicks, providing a seamless experience in a matter of seconds.

One of the standout features of the Needle Grinder machine is its 14 station end effector, which enables simultaneous grinding of up to 14 parts. This machine stands out for its remarkable speed, capable of grinding a 30 gauge needle in as fast as 1.4 seconds. Moreover, it offers versatility by accommodating needle diameters ranging from .008" to .146" using a single end effector, providing a wide range of applications.

Standout Features

Feature 1:

User-Friendly Operator Interface - The Needle Grinder machine's operator interface is designed to be highly user-friendly, with a 24" touchscreen, minimal daily interaction, and integration with in-house software.

Feature 2:

14 Station End Effector for Efficient Production - The machine's end effector has 14 stations with individual collets, allowing for simultaneous setup of collets with the same or various diameters.

Feature 3:

Precise Needle Engagement and Rotation - The Needle Grinder securely holds needles without marks, using a servo motor for rotation accuracy and accommodating needles with hubs or protruding features.

Feature 4:

Automation and Post Process Options - The Needle Grinder system offers automation for loading and unloading cartridges, along with post-process gauging integration for comprehensive data reporting.

In summary, the Needle Grinder machine combines user-friendly operation, high-speed grinding, versatile end effector design, precise needle engagement, and automation features to deliver a comprehensive solution for grinding various types of needles with efficiency and accuracy.

Specifications and

standard features

| Machine Capacity: | .008" - .146" Diameter Needles Minimum Length .500" (12.7mm), No Maximum |

| Needle Styles: |

|

| Robot Model: | Fanuc LR Mate 200iD Repeatability +/- .0004” (+/- .02mm) 6 Axis IP67 Rated Max Load: 7 KG Max Reach: 717 mm |

| Grinding Wheel: | 12" diameter x 16" wide (304mm x 400mm) |

| Spindle Power | 5hp Servo Driven Spindle Consistent SF?M |

| Weight: | 8,800 lbs |

| Dressers | Stepping motor diamond advancement with automatic adjustment for constant wheel surface speed |