Supporting Our Customers Is A Key Priority.

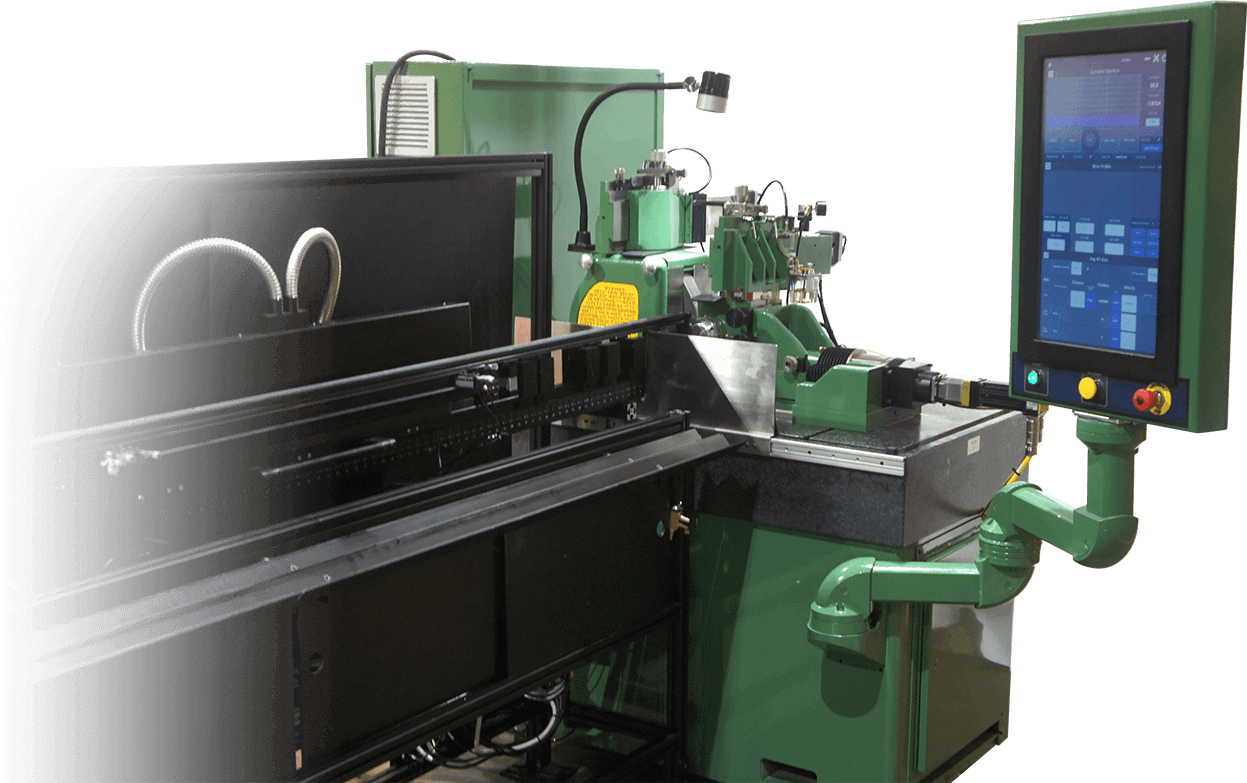

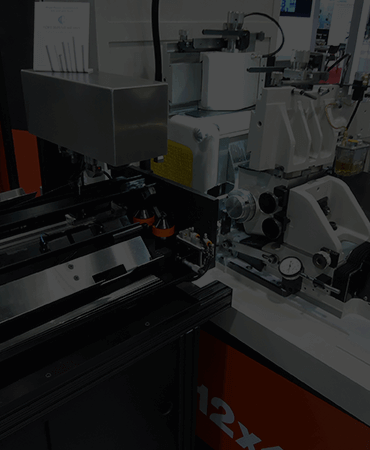

This is the Royal Master Grinders Model TG-12x4 with our updated Generation 5.9 Wire Profile Grinding System. We are pleased to announce the changes to the mechanical machine and the electronic micro processing making the grind system more robust and faster.

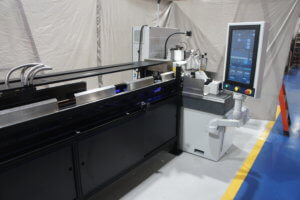

The first thing you notice is the “CLEAN” look to the machine base. No gauges, no hand wheels, no hang on boxes. Everything is “put away” where it belongs. The machine base and the machine bed are both larger to provide a stable platform for the grinding. Coolant containment is enhanced by the broader platform and deeper troughways. Forklift access slots make machine lifting much easier. The machine now sits on our BEDROCK machine bed made of 8” thick Granite.

The Ram Bed Position Control has been updated to use our Precision Ball Screw with Gear Box and Servo Motor. The Servo Motor and Closed Loop Glass Scale have 4 millionths resolution or 1/10th of a micron.

The wheel dressers are now motor driven traverse with Ball Screw movement instead of hydraulic. This makes them digitally controlled on the touch screen HMI.

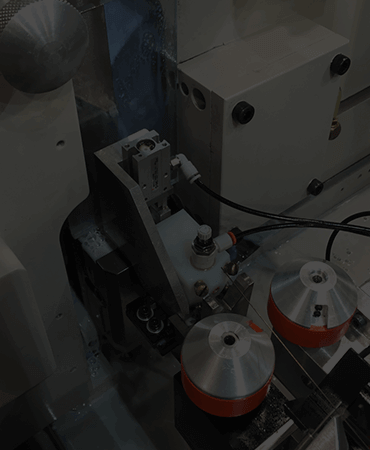

The main components are the same. The grinding wheel, the finger regulating wheel and finger work rest blade. There is a three-inch wheel and blade set up available for better control of tapers and stock removal.

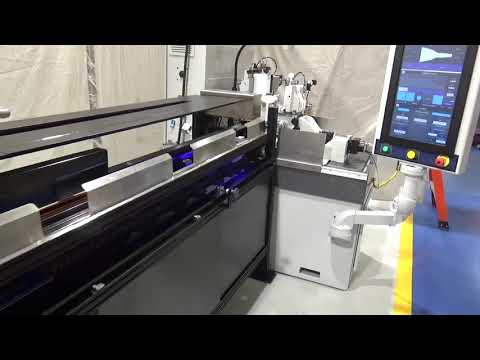

Fully Automatic Wire Loader. 4 second load time and efficient unloading.

We are grinding a paddle wire with multiple tapers. The neck diameter is .004” and body diameter is .030”.

The Electrical Cabinet is integrated to the base of the machine in a floor saving layout.

The new HMI is larger and has a Cleaner Interface. 24” portrait-oriented touch screen with a three panel select option. You can select which of three screens to display and have active on the screen.

The machine controls are windows based which makes this machine capable of remote access for data report sending, connection for remote troubleshooting and ready for automation interface.

The operating system is Windows 10 Pro 64 bit with 3.3 Gigahertz quad core processor, 8 Gigabyte Memory and a 240 Gigabyte Hard Drive. The old system was a Windows XP 32 bit dual core processor with 2.13 Ghz and 2GB Ram.

The Parker Automation Controller replaces the ACR and the old 6V6k. The new system also has IEC61131-3 Programming, High Speed Ether-Cat Controlled Motion and I/O which is faster than ethernet, Dual Core 1.6 Gigahertz 64 bit Processor with 1GB DDR3 Ram.

The Eye Bar is essentially the same except for the Micro Processing eliminating the 3 circuit boards and fiber optic cables. The Eye Bar is an Optical Encoder with a resolution for wire length position of 0.0025”.

The Eye Bar has a Dedicated Micro Controller for reading position. It has a 1.4 Ghz, 64 bit quad core processor. There is a 2.5 millisecond scan time to determine wire position. The information processing time is twice as fast as the previous system. Accurate length reading to 0.0025” (0.0635mm) and wire grind lengths up to 32.5” (825mm), same as current system.

The system interfaces with the Parker Automation Controller via Modbus TCP/IP. The old system interfaced through fiberoptic cables through Mother and Daughter boards then into the Gemini Drive.

We have eliminated the Mother and Daughter boards and Gemini drive. The new Digital Signal Processor is wired directly to Micro Controller eliminating the MUX Board. No need for Fiber Optics, they are replaced with ethernet cable. We removed the Hardware Clock because we now have more control over signal processing making for more accurate grinds.

The HMI can display three screens with active display and interaction. From the Main Navigation Screen, you can select from the icons to make them active.

Operator Interface Screen gives a visual representation of wire position as it is grinding. It will display selectable points on a profile graph. This is typically the screen to have up while grinding.

The Wire Profile Creation Screen is used to create a profile. You can highlight segments by touch, add or insert segments, create segments by entering Start and End Diameter and Length. Save Profile directly to Part Select. This screen will make a template suggestion based on the wire profile.

The Part Select Screen allows you to save an unlimited amount of Part Recipes. You can search for existing profiles by the Recipe name or the Scrollable Window to view parts.

The Part Select Preview Screen allows for easy offline part creation. You can import and export files to use on other Royal Master Grinders or to Backup and save.

With the Windows 10 Pro operating system, we have an easy connection via internet to Team viewer so you can allow us to remote connect for diagnostics.

The new Royal Master Generation 5.9 Wire Profile Grinder is ready for production. We have demonstrated its capabilities with many different grind profiles. The new Gen 5.9 machine has been well received in the marketplace with many installations.

For more information on this product and for an evaluation of how it might benefit your grind application, contact Royal Master Grinders.

THE GENERATION 5.9 IN ACTION

Other Wire Grinding Solutions

TG-12×4 and TG-12×8 Servo Cycle Grinding Systems

The most versatile machine for up to 5 taper wire grinding

Automation of Guidewire Grinding

Operator Assist Devices to Fully Robotic Multitasking Solutions

TG-12×4 and TG-12×8 Basic Guidewire Grinding

Simple Guidewire Grinding made easy and efficient