Supporting Our Customers Is A Key Priority.

Royal Master’s wire profile measurement gauging system has been advancing precision wire grinding since the early 1990s. What began as a straightforward measurement concept has evolved into a fully computerized, high-resolution platform built for today’s data-driven manufacturing environments.

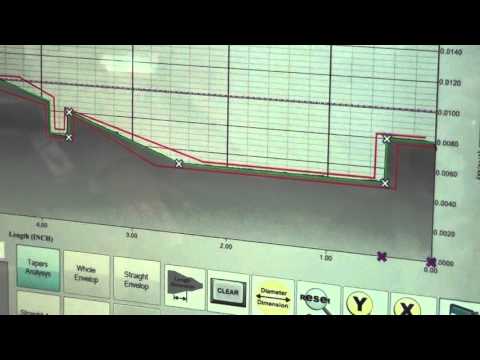

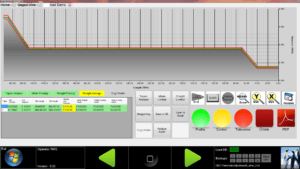

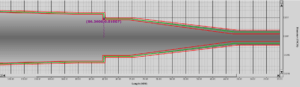

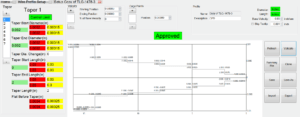

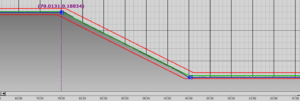

At its core, the system still correlates diameter measurements to linear position and outputs that data graphically. What has changed is the scale and fidelity of the data. The Keyence LS-9006M laser head delivers 16,000 diameter readings per second. That alone is no longer the differentiator. The real breakthrough is pairing those readings with a Yaskawa linear motor offering 0.000009 mm resolution, creating an order-of-magnitude increase in usable linear datapoints.

All measurement data is processed through an industrial-grade PC designed to handle high-volume, high-speed data streams. Users can store data locally, share it across single or multiple facilities, and export directly to Excel templates or standard SPC platforms for statistical analysis and reporting.

System Capabilities

- Diameter range: .001” to .24”

- Repeatability: ±0.03 µm

- Measurement accuracy: .000020”

- Linear resolution: Yaskawa linear motor, .000009 mm

System features

- Granite table for thermal stability on a structural steel frame with casters

- Dual touchscreen monitors

- State-of-the-art i7 industrial PC with dedicated graphics card

- C# software architecture for modern, user-friendly operation

- One sample every .000060” at a pull rate of 1” per second

- Multi-level password-protected screens

- SQL database with unlimited program storage

- Automatic PDF report generation

- Remote viewing of gauged wires

- Automatic wire analysis without printing

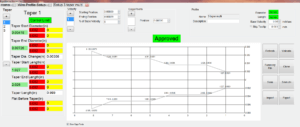

- Pass / Fail measurement summary files

- Absolute or incremental length measurement

- Adaptive algorithms selected automatically to best fit wire geometry

- Whole wire envelope

- Flats envelope

- Flats average diameter

- Control limits with Pass / Pass Adjust / Fail alerts

- High-resolution zoom for detailed wire inspection

- Easy recipe creation system

Laser Gauging System

Other Wire Grinding Solutions

The Cutting Machine

Lorum ipsum dolor sir amet.

Gauging Systems

Gauging of Guidewires and Other Applications

Needle Grinding System

1250 Trocar Needles Per Hour Production Rate Per Machine